What Does A New Gas Furnace Cost

Understanding the cost of a new gas furnace is crucial for homeowners, HVAC technicians, and business owners alike. This comprehensive guide breaks down the factors influencing furnace prices, installation costs, long-term operational expenses, and the impact of technician expertise on overall value. We'll also delve into career opportunities within the gas furnace sector, highlighting the importance of certifications and specialized skills.

Gas Furnace Cost Breakdown: Initial Purchase Price

The upfront cost of a new gas furnace is influenced by several key factors:

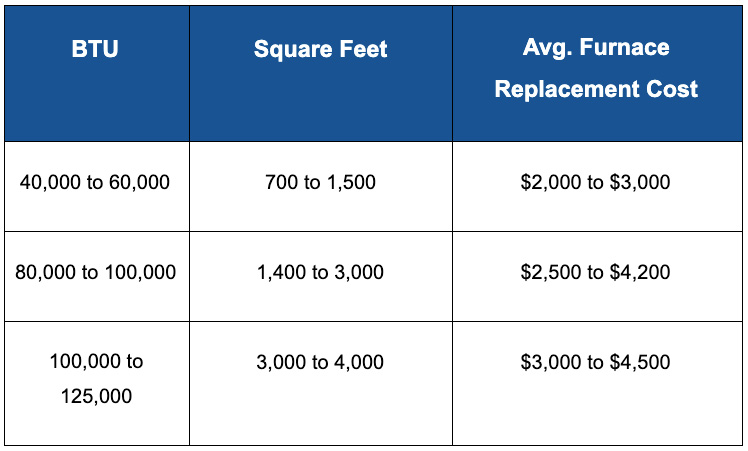

- BTU Rating (British Thermal Units): BTU rating indicates the furnace's heating capacity. Higher BTU furnaces are designed for larger spaces and, therefore, carry a higher price tag. Furnaces typically range from 40,000 BTU to over 120,000 BTU.

- AFUE Rating (Annual Fuel Utilization Efficiency): AFUE represents the furnace's efficiency in converting fuel to heat. An 80% AFUE furnace converts 80% of the fuel into usable heat, while a 95% AFUE furnace is significantly more efficient. Higher AFUE ratings correlate with higher purchase prices but can result in substantial long-term energy savings.

- Furnace Type: Single-stage, two-stage, and modulating furnaces offer varying levels of control and efficiency. Single-stage furnaces operate at a fixed capacity, while two-stage furnaces offer two output levels, and modulating furnaces adjust their output continuously to precisely match heating demand. Modulating furnaces are the most expensive initially but provide the greatest comfort and efficiency.

- Brand Reputation: Established brands with a reputation for reliability and performance often command a premium price. Brands like Carrier, Trane, Lennox, and Goodman are widely recognized and respected within the HVAC industry.

As of late 2024, homeowners can generally expect to pay the following for the furnace unit alone:

- 80% AFUE Furnace: $2,000 - $4,000

- 90%+ AFUE Furnace: $3,500 - $6,000

Installation Costs: Beyond the Unit Price

Installation costs can significantly add to the overall expense of a new gas furnace. Factors influencing installation pricing include:

- Labor Costs: Labor rates vary depending on location and the experience level of the HVAC technician. Hourly rates can range from $75 to $150 or more.

- Ductwork Modifications: Existing ductwork may need modifications or replacement to accommodate the new furnace. This can add significantly to the cost, particularly in older homes.

- Permits and Inspections: Local building codes often require permits and inspections for furnace installations. These fees can range from $50 to $500 or more, depending on the municipality.

- Removal of Old Furnace: Removing and disposing of the old furnace typically incurs an additional charge.

- Additional Components: Costs for new thermostats, gas lines, venting, and other necessary components also contribute to the overall installation price.

Homeowners should expect to pay between $1,500 and $5,000 for installation, depending on the complexity of the project. It's always recommended to obtain multiple quotes from licensed and insured HVAC contractors.

Total Cost Considerations: A Real-World Example

Let's consider a scenario: A homeowner in a suburban area needs to replace an aging 80,000 BTU furnace. They opt for a 95% AFUE model from a reputable brand. The furnace unit itself costs $4,500. Installation requires minor ductwork modifications, a new thermostat, and removal of the old unit. The total installation cost comes to $3,000. In this case, the total cost of the new furnace installation is $7,500.

Long-Term Operating Costs: Efficiency Matters

While the initial cost is a significant consideration, long-term operating costs are equally important. A higher AFUE furnace will save homeowners money on their energy bills over the furnace's lifespan. Consider a comparison:

- 80% AFUE: For every dollar spent on natural gas, 80 cents goes towards heating the home.

- 95% AFUE: For every dollar spent on natural gas, 95 cents goes towards heating the home.

Over a 15-20 year lifespan, the energy savings from a high-efficiency furnace can easily offset the higher initial purchase price. Factors such as local gas prices, climate, and home insulation levels will impact the actual savings.

The Importance of Professional HVAC Technicians

The skills and expertise of the HVAC technician are critical for proper furnace installation and maintenance. A poorly installed furnace can operate inefficiently, leading to higher energy bills and potential safety hazards. Proper sizing of the furnace to the home's heating load is also crucial for optimal performance.

Certifications: Certifications such as NATE (North American Technician Excellence) demonstrate a technician's competency and commitment to quality. EPA 608 certification is mandatory for technicians handling refrigerants. Employers often prioritize hiring certified technicians, and certifications can lead to higher earning potential.

Career Paths: A career in HVAC offers diverse opportunities, from installation and maintenance to system design and sales. Experienced technicians can specialize in specific areas, such as gas furnaces, heat pumps, or commercial HVAC systems. Management and leadership roles are also available for those with strong technical skills and business acumen. The Bureau of Labor Statistics projects a strong job outlook for HVAC technicians in the coming years.

Salary Expectations for HVAC Professionals

Salaries for HVAC technicians vary depending on experience, location, and certifications. According to recent data, the median annual salary for HVAC technicians in the United States is around $50,000. However, experienced technicians with specialized skills and certifications can earn significantly more, with some earning over $80,000 per year. Those in supervisory or management positions can earn even higher salaries.

Employer Considerations: Hiring and Training

For HVAC businesses, investing in skilled technicians is essential for providing quality service and maintaining a competitive edge. Employers should prioritize hiring technicians with relevant certifications and provide ongoing training to keep their skills up-to-date. Offering competitive salaries and benefits is also crucial for attracting and retaining top talent.

Industry Trends: The Future of Gas Furnaces

The HVAC industry is constantly evolving, with new technologies and regulations emerging. One significant trend is the increasing focus on energy efficiency and sustainability. Manufacturers are developing more efficient gas furnaces that meet stricter environmental standards. Smart thermostats and home automation systems are also becoming increasingly popular, allowing homeowners to control their heating systems remotely and optimize energy usage.

As concerns about climate change grow, there is also increasing interest in alternative heating technologies, such as heat pumps and renewable energy systems. However, gas furnaces are likely to remain a popular choice for many homeowners, particularly in colder climates, due to their affordability and reliability.

Making Informed Decisions

Understanding the costs and benefits of different gas furnace options is essential for making informed decisions. Homeowners should carefully consider their budget, energy needs, and long-term operating costs when choosing a new furnace. Consulting with a qualified HVAC technician can help ensure that the furnace is properly sized and installed for optimal performance and efficiency. For HVAC professionals, continuous learning and skill development are essential for staying ahead in a competitive industry. Employers should focus on attracting, training, and retaining skilled technicians to provide quality service and meet the evolving needs of their customers.