What Does A Pressure Relief Valve Look Like

Understanding Your HVAC System's Pressure Relief Valve: A Visual Guide

Your HVAC system, particularly the heating side, relies on pressure to operate efficiently. However, excessive pressure can be dangerous and cause significant damage. That's where the pressure relief valve (PRV) comes in. This often-overlooked component is a critical safety device designed to prevent explosions and system failures. But what does a pressure relief valve look like, and where can you find it? This guide will help you identify it, understand its function, and know when to call a professional.

Identifying the Pressure Relief Valve: A Visual Tour

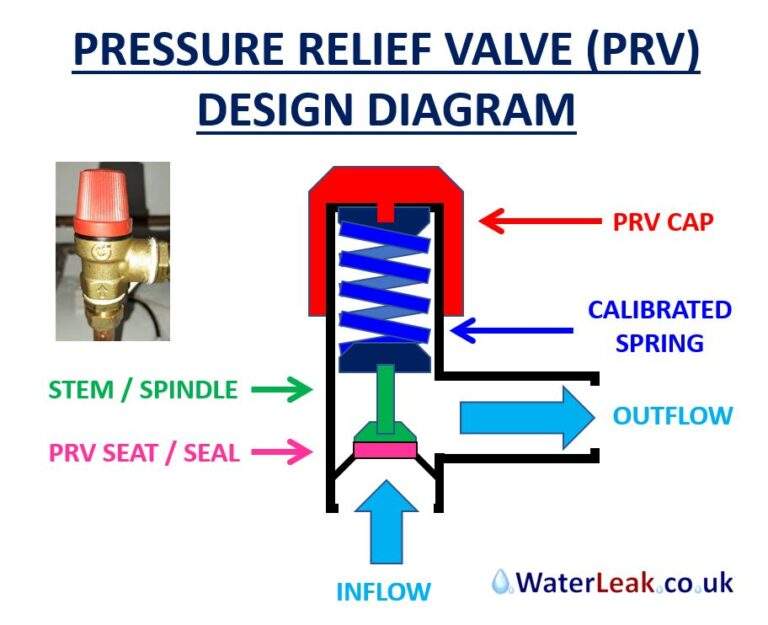

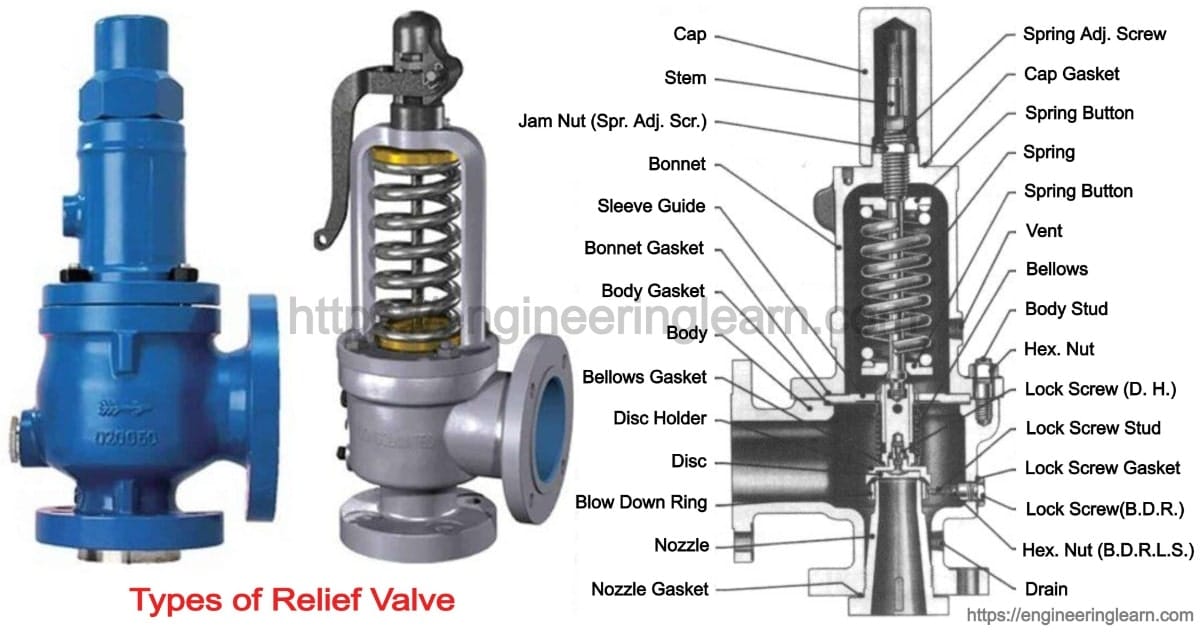

The appearance of a pressure relief valve can vary slightly depending on the type of system (boiler, water heater, etc.) and the manufacturer. However, there are some common characteristics to look for.

- Location, Location, Location: The PRV is typically found on or near the boiler, water heater, or expansion tank. It's usually mounted on the top or side of the unit.

- Shape and Size: PRVs are generally small, metallic, and cylindrical or cone-shaped. Sizes range, but most residential PRVs are between 2 and 4 inches in length.

- Material: They are commonly made of brass or bronze, but some newer models might use stainless steel or durable plastic components.

- Discharge Pipe: Crucially, a PRV will almost always have a discharge pipe extending from it. This pipe is designed to direct any released steam or water safely away from the equipment and personnel. The discharge pipe should be made of a material suitable for high temperatures, such as copper or CPVC. It should terminate 6-12 inches above the floor or into a drain, and never be capped or plugged.

- Lever or Handle: Most PRVs have a lever or handle used for manual testing. This lever allows you to manually release pressure to ensure the valve is functioning correctly.

- Pressure Rating: The valve will have a pressure rating stamped or engraved on its body. This indicates the maximum pressure the valve is designed to withstand before automatically releasing. This is typically measured in PSI (pounds per square inch).

Different Types of Pressure Relief Valves You Might Encounter

While the basic function remains the same, PRVs can differ slightly in design:

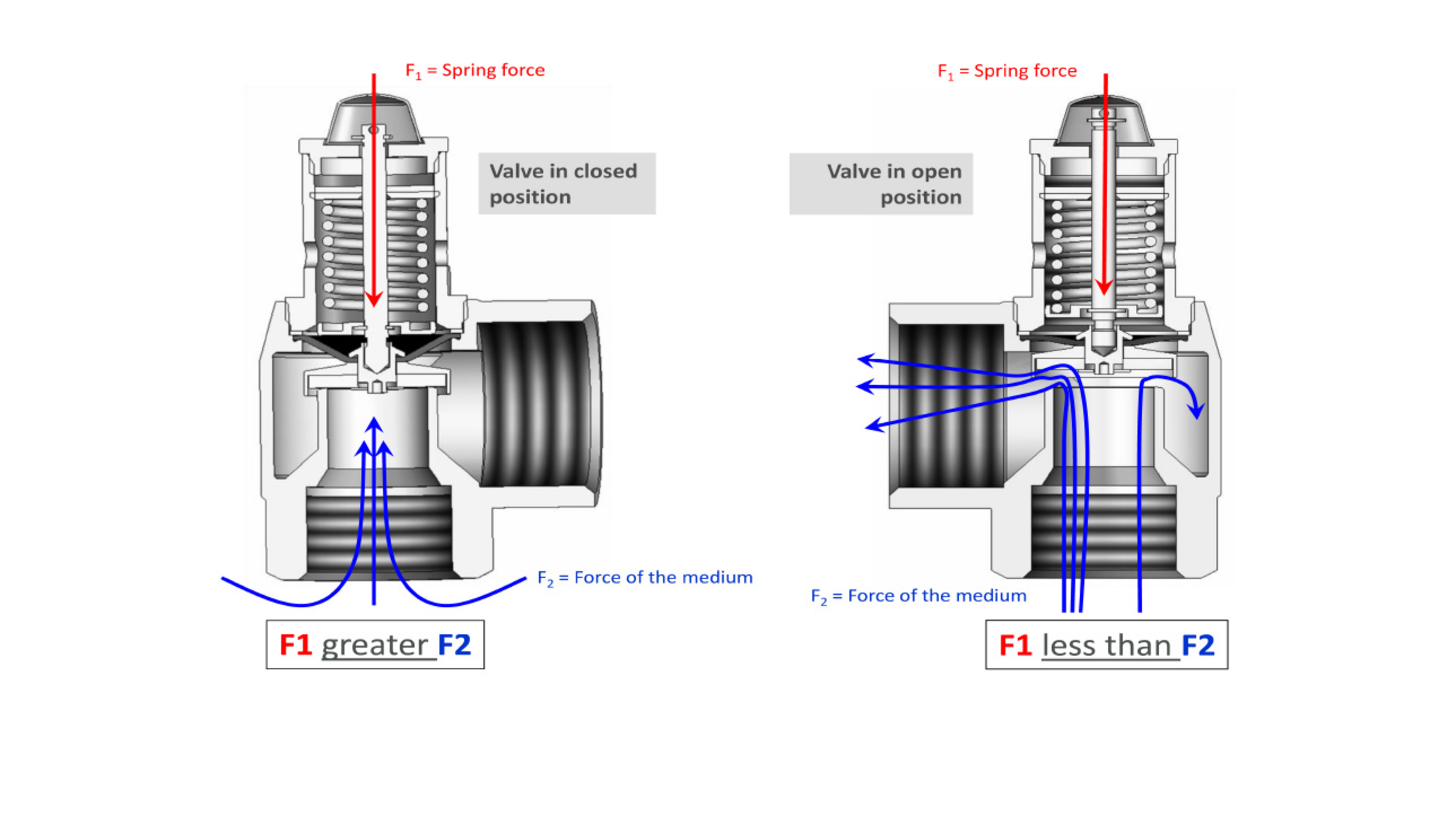

- Spring-Loaded Relief Valves: These are the most common type. A spring holds a valve closed until the pressure exceeds the setpoint, at which point the spring compresses, and the valve opens to release the excess pressure.

- Temperature and Pressure Relief Valves (T&P Valves): Commonly found on water heaters, these valves are designed to relieve pressure and temperature. They have a temperature-sensing element that will trigger the valve to open if the water temperature exceeds a safe limit (usually around 210°F).

- Diaphragm Relief Valves: These use a diaphragm instead of a spring to control the valve opening. They are often used in lower-pressure applications.

What to Do if You Think You've Found a Pressure Relief Valve

Once you think you've located a PRV, observe its condition and the surrounding area. Here's what to look for:

- Signs of Leaking: Look for water stains, corrosion, or mineral deposits around the valve and discharge pipe. Even a small, persistent drip can indicate a problem.

- Proper Discharge Pipe Installation: Verify that the discharge pipe is properly installed, terminating safely above the floor or into a drain. Make sure the pipe is not blocked or restricted in any way.

- Check the Pressure Gauge: If your system has a pressure gauge, check the reading. It should be within the normal operating range specified in your system's manual.

Troubleshooting a Pressure Relief Valve: DIY vs. Professional Help

Some simple troubleshooting steps can be performed safely by homeowners. However, always prioritize safety and know your limits. If you're uncomfortable with any of these steps, call a qualified HVAC technician.

DIY Troubleshooting (Proceed with Caution!)

- Manual Test: Gently lift the lever on the PRV to manually release some pressure. This should cause water to flow through the discharge pipe. Release the lever, and the valve should snap closed, stopping the flow of water. Caution: The water may be very hot. Wear appropriate safety gear (gloves, eye protection).

- Inspect the Discharge Pipe: Ensure the discharge pipe is clear of obstructions. Remove any debris that might be blocking the pipe.

- Check System Pressure: Consult your owner's manual to determine the proper operating pressure for your system. If the pressure is too high, there may be an underlying issue causing the problem (e.g., a faulty expansion tank).

When to Call a Professional

The following situations require the expertise of a qualified HVAC technician:

- Continuous Leaking: If the PRV is constantly leaking, even after a manual test, it likely needs to be replaced.

- High System Pressure: If the system pressure is consistently above the recommended level, there's an underlying problem that needs to be diagnosed and repaired. This could be a faulty expansion tank, a malfunctioning control system, or another issue.

- No Discharge During Manual Test: If no water flows when you lift the lever, the valve may be clogged or defective.

- Corrosion or Damage: If the PRV is visibly corroded or damaged, it should be replaced immediately.

- Unfamiliar with Your System: If you are unsure about any aspect of your HVAC system, or are uncomfortable working with it, always call a professional.

Estimated Repair Costs

Replacing a pressure relief valve typically costs between $100 and $300, including parts and labor. The exact cost will depend on the type of valve, the complexity of the installation, and the labor rates in your area. If the underlying problem causing the PRV to fail is more complex (e.g., a faulty expansion tank), the repair costs could be significantly higher.

Important Safety Note: Working with HVAC systems can be dangerous. Always disconnect power to the equipment before performing any maintenance or repairs. If you're unsure about any aspect of the work, call a qualified HVAC technician. Improper repairs can lead to serious injury or property damage.

Preventing PRV Problems

Regular maintenance can help prevent PRV failures and extend the life of your HVAC system:

- Annual Inspection: Have your HVAC system inspected annually by a qualified technician. They can check the condition of the PRV and identify any potential problems.

- Monitor System Pressure: Keep an eye on the system pressure gauge. If you notice any significant fluctuations or consistently high readings, contact a professional.

- Flush Your Water Heater: Regularly flush your water heater to remove sediment buildup. Sediment can clog the PRV and reduce its effectiveness.

Tools and Parts You Might Need (For Simple Tasks)

If you're comfortable performing simple tasks like testing the PRV or clearing a blocked discharge pipe, here are some tools and parts you might need:

- Adjustable Wrench: For loosening and tightening fittings.

- Pipe Wrench: For larger pipes and fittings.

- Screwdrivers (Various sizes): For removing access panels and other components.

- Gloves: To protect your hands from hot water and sharp edges.

- Eye Protection: To protect your eyes from debris.

- Bucket: To catch water during testing or repairs.

- Replacement PRV: If the valve needs to be replaced (make sure it's the correct type and pressure rating).

- Pipe Joint Compound (Teflon Tape): For sealing pipe threads.

Common Pressure Relief Valve Issues

Here's a quick recap of common PRV problems and their potential causes:

- Leaking: Can be caused by a faulty valve, high system pressure, or sediment buildup.

- No Discharge During Manual Test: Can be caused by a clogged valve, a defective valve, or low system pressure.

- High System Pressure: Can be caused by a faulty expansion tank, a malfunctioning control system, or a blockage in the system.

- Corrosion: Can be caused by age, exposure to moisture, or chemical imbalances in the water.

By understanding what a pressure relief valve looks like, how it functions, and the potential problems it can experience, you can take proactive steps to maintain your HVAC system and ensure its safe and efficient operation. Remember, when in doubt, always consult a qualified HVAC professional.