What Happens If You Inhale Ac Gas

Refrigerant, commonly called "AC gas," is the lifeblood of any air conditioning and refrigeration system. It's what allows these systems to transfer heat, keeping our homes, offices, and food storage facilities cool. But while essential, refrigerant poses significant health risks if inhaled. Understanding these risks is crucial for HVAC technicians, apprentices, and anyone working around these systems, as well as for employers ensuring workplace safety.

Understanding Refrigerant Types and Their Risks

The type of refrigerant significantly influences the severity of potential health effects. Older refrigerants, like R-22 (Freon), are being phased out due to their ozone-depleting potential. Newer refrigerants, such as R-410A (Puron) and R-32, are more environmentally friendly but still pose health hazards. And emerging refrigerants like R-1234yf are being adopted, but their long-term health effects are still being studied.

Here's a breakdown of common refrigerants and their associated inhalation risks:

- R-22 (Freon): While being phased out, many older systems still use R-22. Inhalation can cause dizziness, nausea, headaches, and, in high concentrations, irregular heartbeat and loss of consciousness.

- R-410A (Puron): A common replacement for R-22, R-410A poses similar risks. Inhaling high concentrations can lead to respiratory irritation, cardiac sensitization, and central nervous system depression.

- R-32: Increasingly used due to its lower global warming potential, R-32 can cause dizziness, drowsiness, and respiratory irritation upon inhalation.

- R-134a: Commonly found in automotive AC systems, R-134a inhalation can lead to heart palpitations, dizziness, and asphyxiation in enclosed spaces.

- Ammonia (NH3): Used in industrial refrigeration systems, ammonia is highly toxic. Inhalation can cause severe respiratory burns, pulmonary edema, and even death. Exposure to ammonia requires immediate medical attention.

Regardless of the specific refrigerant, the primary dangers of inhalation stem from:

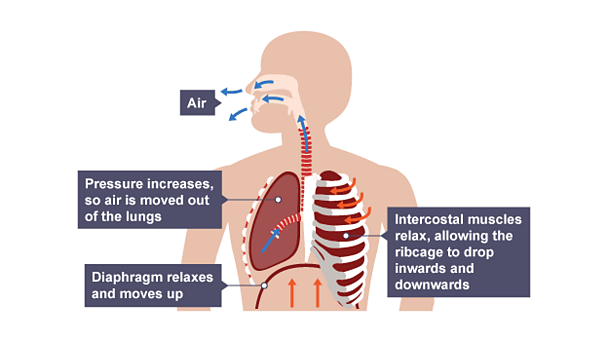

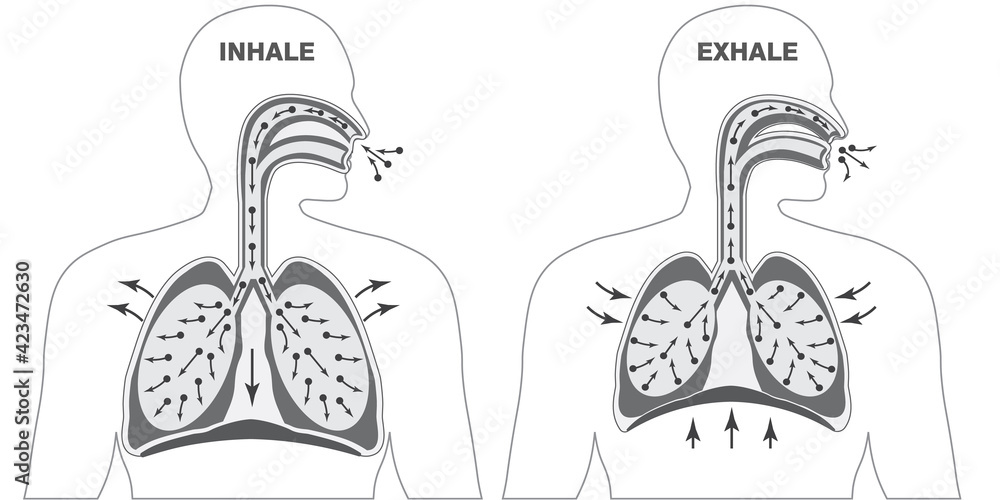

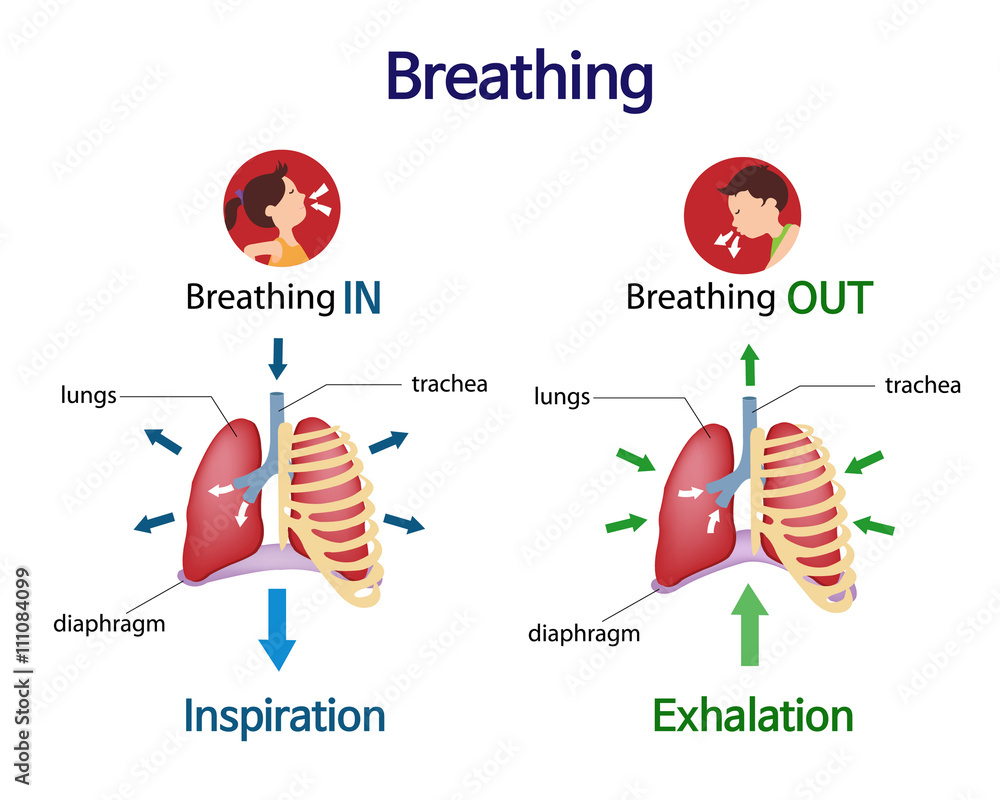

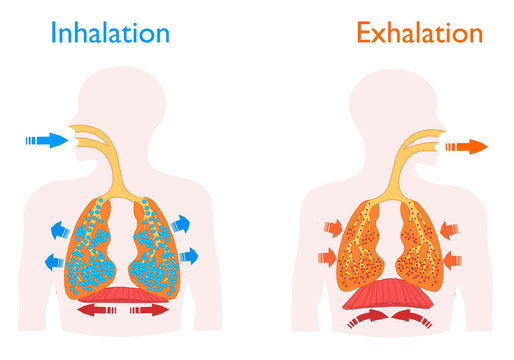

- Oxygen Displacement: High concentrations of refrigerant can displace oxygen in the lungs, leading to asphyxiation.

- Cardiac Sensitization: Some refrigerants can sensitize the heart to adrenaline, potentially leading to irregular heartbeat and cardiac arrest.

- Central Nervous System Depression: Refrigerant inhalation can depress the central nervous system, causing dizziness, confusion, loss of coordination, and unconsciousness.

- Respiratory Irritation: Many refrigerants are respiratory irritants, causing coughing, shortness of breath, and pulmonary edema (fluid in the lungs).

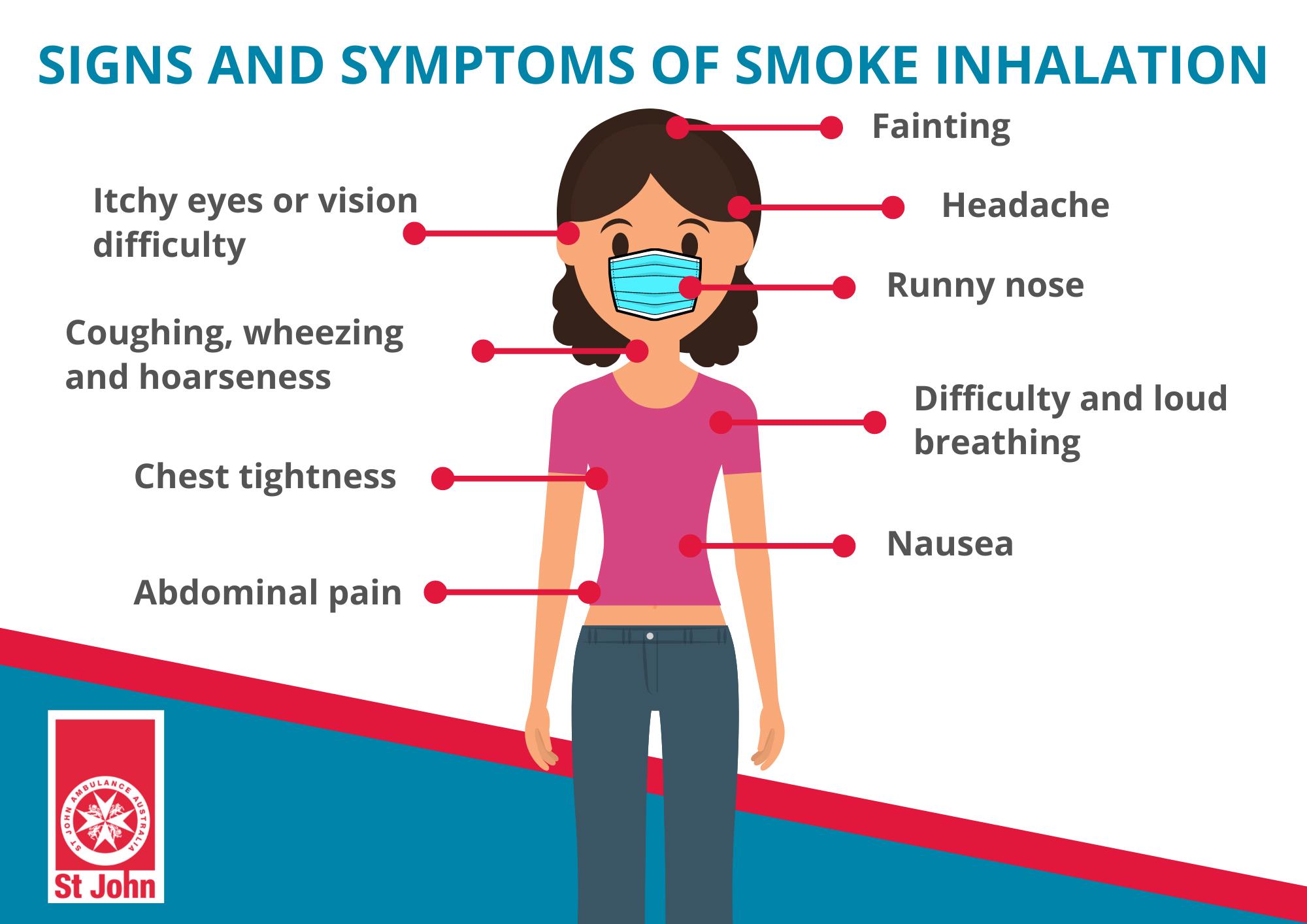

Symptoms of Refrigerant Inhalation

The symptoms of refrigerant inhalation vary depending on the type and concentration of refrigerant, as well as the duration of exposure. Common symptoms include:

- Headache

- Dizziness

- Nausea and vomiting

- Coughing and shortness of breath

- Eye and skin irritation

- Heart palpitations or irregular heartbeat

- Confusion or disorientation

- Loss of consciousness

- Seizures (in severe cases)

If you suspect refrigerant inhalation, it's crucial to seek fresh air immediately and seek medical attention. Don't underestimate the potential severity of the situation, even if symptoms seem mild at first.

Prevention is Key: Safety Measures for HVAC Professionals

The best way to avoid the dangers of refrigerant inhalation is to implement strict safety protocols. This is where proper training and certification are essential. Some key preventive measures include:

- Proper Ventilation: Always work in well-ventilated areas, especially when handling refrigerants.

- Personal Protective Equipment (PPE): Wear appropriate PPE, including gloves, safety glasses, and respirators, when handling refrigerants. The type of respirator needed will depend on the refrigerant being used and the potential concentration in the air.

- Leak Detection: Regularly inspect equipment for leaks and repair them promptly. Use electronic leak detectors to identify even small leaks.

- Proper Handling Procedures: Follow established procedures for refrigerant recovery, charging, and disposal. Avoid overfilling systems.

- Emergency Procedures: Be familiar with emergency procedures for refrigerant leaks, including evacuation plans and first aid measures.

- Training and Certification: Participate in ongoing training programs to stay up-to-date on refrigerant safety and handling practices.

The Importance of HVAC Certifications

Certification plays a crucial role in ensuring that HVAC technicians are properly trained and competent to handle refrigerants safely. Several certifications are relevant, including:

- EPA Section 608 Certification: Required by law for technicians who handle refrigerants during the service, maintenance, or disposal of air conditioning and refrigeration equipment. This certification demonstrates competency in refrigerant recovery, recycling, and handling procedures.

- NATE (North American Technician Excellence) Certification: A voluntary certification that demonstrates a technician's knowledge and skills in specific areas of HVAC, such as installation, service, and efficiency. NATE certification can enhance career prospects and demonstrate a commitment to professionalism.

- HVAC Excellence Certification: Another respected certification that validates a technician's skills and knowledge in various HVAC areas.

Earning these certifications not only improves safety but also enhances career opportunities. According to the U.S. Bureau of Labor Statistics, the median annual wage for HVAC technicians was $51,390 in May 2022. The job outlook is projected to grow 6 percent from 2022 to 2032, about as fast as the average for all occupations. However, technicians with advanced skills and certifications, particularly in areas like energy efficiency and refrigerant handling, are likely to be in higher demand.

Career Paths in HVAC and Refrigerant Safety

A career in HVAC offers diverse paths, from installation and maintenance to system design and energy management. Understanding refrigerant safety is crucial for success in any of these roles.

Here are a few examples of career paths where refrigerant safety knowledge is essential:

- HVAC Technician: Installs, maintains, and repairs heating, ventilation, and air conditioning systems. Requires a strong understanding of refrigerant handling and safety procedures.

- Refrigeration Technician: Specializes in the installation and maintenance of refrigeration systems in commercial and industrial settings. Must be proficient in handling various refrigerants and diagnosing refrigerant leaks.

- HVAC System Designer: Designs and specifies HVAC systems for buildings, considering energy efficiency, indoor air quality, and refrigerant options.

- Energy Auditor: Assesses the energy efficiency of buildings and recommends improvements, including upgrades to HVAC systems and refrigerant replacements.

- HVAC Instructor: Teaches HVAC principles and practices to students and apprentices, emphasizing safety and proper refrigerant handling.

Real-world Example: Consider Maria, a recent HVAC graduate. She prioritized obtaining her EPA 608 certification and took additional courses on refrigerant safety. This made her a highly sought-after candidate, and she quickly landed a job with a reputable HVAC company. Her commitment to safety and her strong understanding of refrigerants have allowed her to excel in her role and advance her career.

Employer Responsibilities: Creating a Safe Work Environment

Employers in the HVAC industry have a legal and ethical responsibility to provide a safe working environment for their employees. This includes:

- Providing comprehensive training on refrigerant safety and handling procedures.

- Supplying appropriate PPE, including respirators, gloves, and safety glasses.

- Ensuring that equipment is properly maintained and inspected for leaks.

- Developing and implementing emergency procedures for refrigerant leaks.

- Complying with all applicable regulations regarding refrigerant handling and disposal.

Investing in safety training and equipment is not only the right thing to do but also makes good business sense. By creating a safe work environment, employers can reduce the risk of accidents, injuries, and regulatory fines, while also improving employee morale and productivity.

The Future of Refrigerants: Sustainable Alternatives and Ongoing Research

The HVAC industry is constantly evolving, with a focus on developing more sustainable and environmentally friendly refrigerants. Ongoing research is exploring new refrigerants with lower global warming potential (GWP) and improved energy efficiency.

As new refrigerants are introduced, it's crucial for HVAC professionals to stay informed about their properties, handling requirements, and potential health risks. Continuing education and training are essential for keeping up with the latest advancements in refrigerant technology.

In conclusion, understanding the risks associated with refrigerant inhalation is paramount for anyone working in the HVAC industry. By prioritizing safety, obtaining relevant certifications, and staying informed about new refrigerants and technologies, HVAC professionals can protect themselves and their colleagues while contributing to a more sustainable future.