What Happens If You Run Your Ac Without Freon

As an HVAC career advisor and industry analyst, I frequently encounter questions about system operation and maintenance. One question that consistently surfaces, especially among students and new technicians, is: "What happens if you run your AC without Freon?" The short answer is: it's a recipe for disaster. This article will delve into the details of why operating an AC unit without refrigerant, the lifeblood of the system, is detrimental, and how to prevent it. We'll also explore the implications for your career in the HVAC industry.

The Role of Refrigerant in Air Conditioning

Before we discuss the consequences of running an AC unit without refrigerant, it’s crucial to understand the vital role refrigerant plays in the cooling process. Refrigerant, commonly referred to as Freon (though that's a specific brand name; newer systems use different refrigerants like R-410A or R-32), circulates through the AC system, absorbing heat from inside your home and releasing it outside. This phase change process – from liquid to gas and back again – is what makes cooling possible. Without refrigerant, there's no heat transfer, and thus, no cooling.

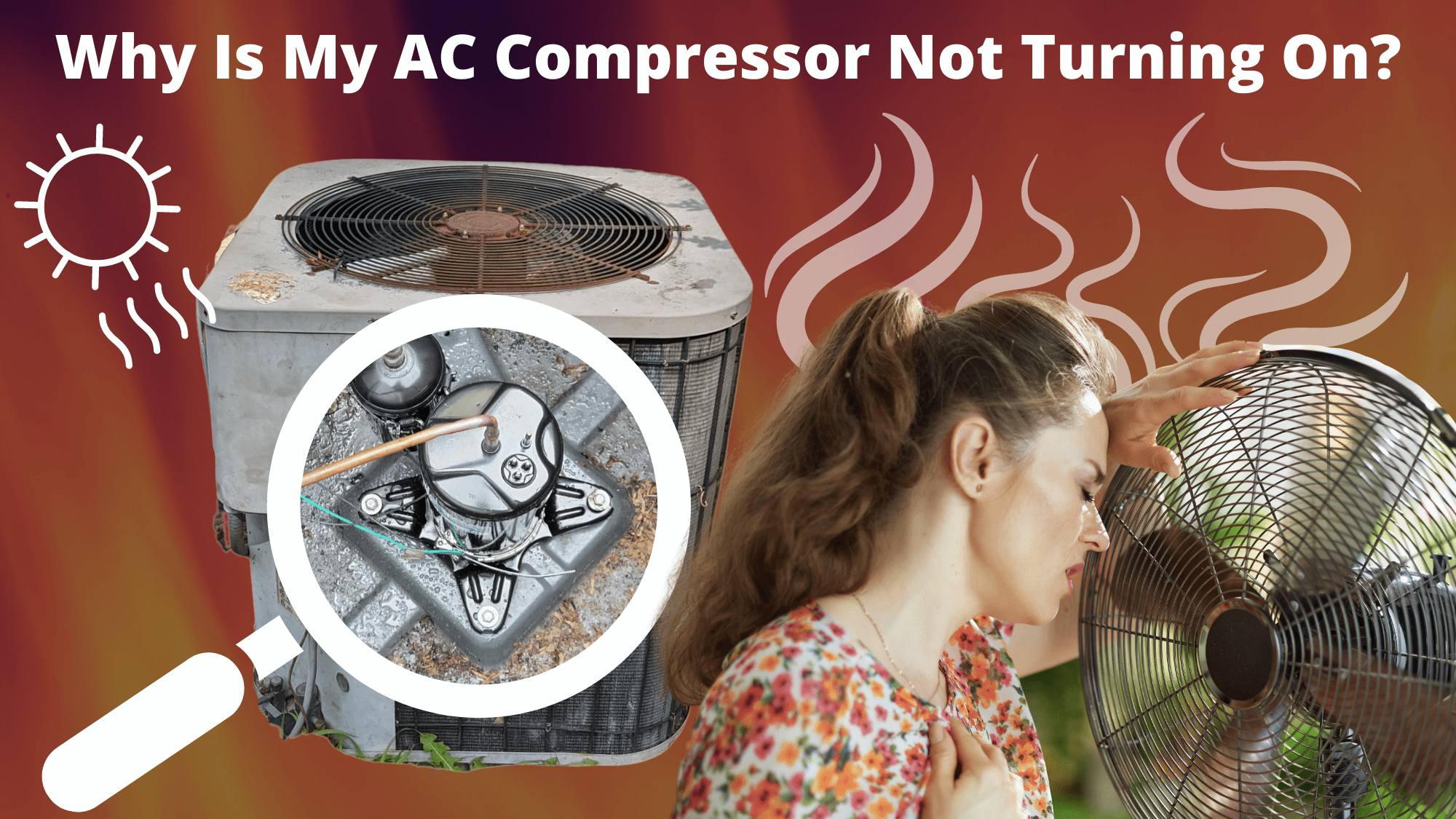

Consequences of Running an AC Without Refrigerant

Operating your AC unit without sufficient refrigerant (or none at all) leads to a cascade of problems, ultimately causing significant damage and potentially shortening the lifespan of the equipment.

Compressor Damage

The compressor is the heart of your AC system, responsible for compressing the refrigerant and circulating it throughout the system. When refrigerant levels are low, the compressor has to work harder to achieve the desired pressure. Without refrigerant acting as a coolant and lubricant, the compressor overheats. This overheating can lead to:

- Burnout: Excessive heat can cause the compressor's internal components to melt or seize, rendering it inoperable.

- Winding Damage: The motor windings within the compressor can become damaged due to overheating and lack of proper cooling.

- Reduced Lifespan: Even if the compressor doesn't fail immediately, running it under such stress significantly shortens its lifespan. Replacing a compressor is one of the most expensive AC repairs, often costing hundreds or even thousands of dollars.

Evaporator Coil Freeze-Up

While it seems counterintuitive, a lack of refrigerant can actually cause the evaporator coil (the indoor coil that absorbs heat) to freeze. Here's why: refrigerant absorbs heat as it changes from a liquid to a gas. With insufficient refrigerant, the coil becomes too cold, causing moisture in the air to condense and freeze on its surface. This ice buildup restricts airflow, further reducing cooling efficiency and potentially damaging the coil.

Increased Energy Consumption

An AC system operating without adequate refrigerant will struggle to cool your home, resulting in longer run times and increased energy consumption. You'll notice higher electricity bills without experiencing the desired level of comfort. The system is essentially working overtime but achieving little to no results.

Potential Damage to Other Components

The strain on the compressor and the freeze-up of the evaporator coil can indirectly affect other components within the AC system, such as the blower motor, expansion valve, and ductwork. These components may become damaged due to the increased stress and inefficient operation of the system.

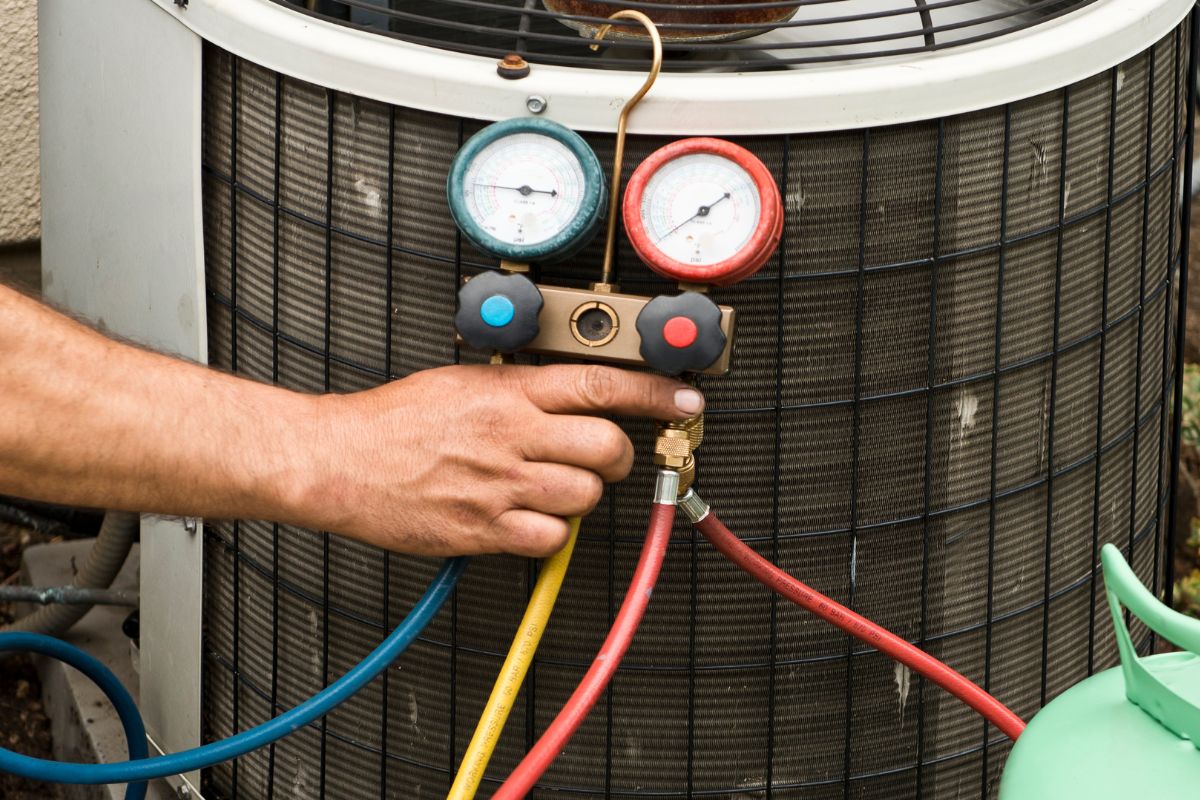

Diagnosing Refrigerant Leaks

The most common reason for low refrigerant levels is a leak in the system. Identifying and repairing refrigerant leaks is a critical skill for HVAC technicians. Common methods for leak detection include:

- Soap Bubble Test: Applying a soapy solution to suspected leak areas and looking for bubbles.

- Electronic Leak Detectors: Using specialized devices that detect the presence of refrigerant in the air.

- UV Dye Detection: Adding a UV-sensitive dye to the refrigerant and using a UV light to identify leaks.

The Importance of EPA 608 Certification

Handling refrigerants is a regulated activity. The EPA (Environmental Protection Agency) requires technicians who handle refrigerants to be certified under Section 608 of the Clean Air Act. This certification ensures that technicians are trained in proper refrigerant handling procedures, including recovery, recycling, and reclamation. There are different types of EPA 608 certifications, depending on the type of equipment a technician works with. Obtaining your EPA 608 certification is crucial for anyone pursuing a career in HVAC.

NATE Certification: Enhancing Your HVAC Career

While EPA 608 certification is legally required, NATE (North American Technician Excellence) certification is a voluntary credential that demonstrates a technician's knowledge and skills. NATE-certified technicians are often viewed as more qualified and reliable by employers and customers. Earning NATE certification can lead to better job opportunities and higher earning potential. NATE offers certifications in various HVAC specialties, such as air conditioning, heat pumps, and gas furnaces.

HVAC Career Outlook and Salary Expectations

The demand for skilled HVAC technicians is expected to grow significantly in the coming years. According to the U.S. Bureau of Labor Statistics, the job outlook for HVAC mechanics and installers is projected to grow 6 percent from 2022 to 2032, about as fast as the average for all occupations. This growth is driven by factors such as new construction, increasing demand for energy-efficient systems, and the need to replace aging equipment.

The median annual wage for HVAC mechanics and installers was $59,620 in May 2023. The best-paid 10 percent earned more than $82,950, while the lowest-paid 10 percent earned less than $36,380. Salary can vary depending on experience, location, certifications, and the specific type of work performed. Entry-level positions may start around $35,000-$40,000 per year, while experienced technicians with advanced certifications can earn well over $70,000 annually.

Career Paths in HVAC

The HVAC industry offers a variety of career paths, including:

- HVAC Technician: Installing, maintaining, and repairing HVAC systems in residential and commercial buildings.

- HVAC Installer: Specializing in the installation of new HVAC systems.

- HVAC Service Technician: Focusing on the maintenance and repair of existing HVAC systems.

- HVAC Sales Engineer: Designing and selling HVAC systems to commercial clients.

- HVAC Project Manager: Overseeing the installation and maintenance of HVAC systems for large projects.

- HVAC Business Owner: Starting and running your own HVAC company.

Real-world example: Consider Sarah, a recent graduate of an HVAC technical school. She obtained her EPA 608 certification and started working as an entry-level HVAC technician for a local company. After gaining a few years of experience, she pursued NATE certification in air conditioning. This certification helped her land a higher-paying position with a larger company, where she now specializes in servicing complex commercial HVAC systems. Sarah's commitment to education and certification has significantly advanced her career in the HVAC industry.

Preventing Issues Related to Low Refrigerant

The best way to avoid the problems associated with running an AC without refrigerant is to prevent leaks in the first place. Regular maintenance, including annual inspections by a qualified HVAC technician, can help identify and address potential issues before they become major problems. During a maintenance visit, the technician will check refrigerant levels, inspect for leaks, clean coils, and perform other essential tasks to ensure optimal system performance.

Conclusion

Operating an AC unit without refrigerant is a surefire way to damage your equipment and waste energy. Understanding the vital role of refrigerant and the consequences of its absence is essential for both homeowners and HVAC professionals. For aspiring technicians, obtaining the necessary certifications (EPA 608 and NATE) and continuously updating your skills will pave the way for a successful and rewarding career in this growing industry. For employers, investing in training and certification for your technicians ensures high-quality service and customer satisfaction. Remember, a well-maintained AC system is an efficient and reliable system. Prioritize regular maintenance and address any refrigerant leaks promptly to keep your system running smoothly for years to come.