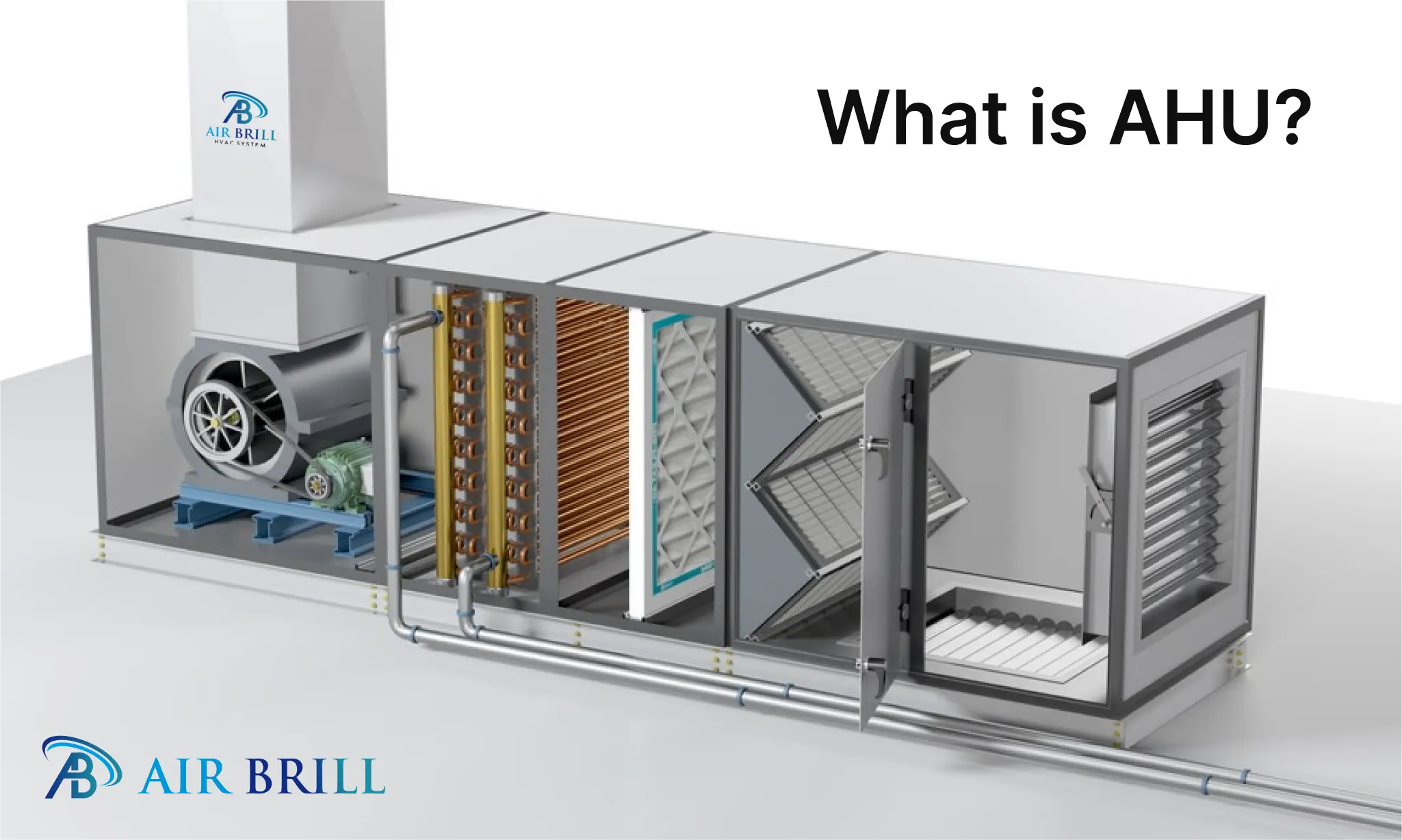

What Is A Air Handling Unit

Understanding the Air Handling Unit: The Heart of Your HVAC System

The Air Handling Unit (AHU) is a critical component of many Heating, Ventilation, and Air Conditioning (HVAC) systems, responsible for conditioning and circulating air within a building. While often associated with larger commercial or industrial buildings, smaller AHUs can also be found in residential settings. Understanding what an AHU does, its components, and its benefits is crucial for homeowners, HVAC technicians, and facility managers alike.

What Does an Air Handling Unit Do?

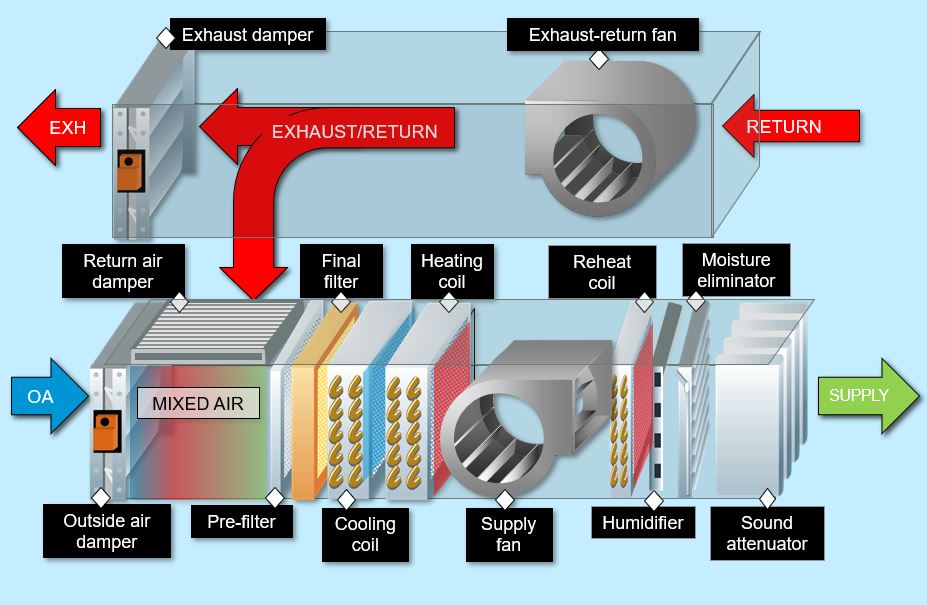

Essentially, an AHU takes in outside air and/or recirculated air from within the building, conditions it (heats, cools, humidifies, or dehumidifies), and then circulates it through ductwork into the occupied spaces. This process ensures consistent temperature, humidity, and air quality throughout the building. Unlike simpler systems like window air conditioners, AHUs offer centralized control and often incorporate sophisticated filtration and air treatment technologies.

Key Components of an Air Handling Unit

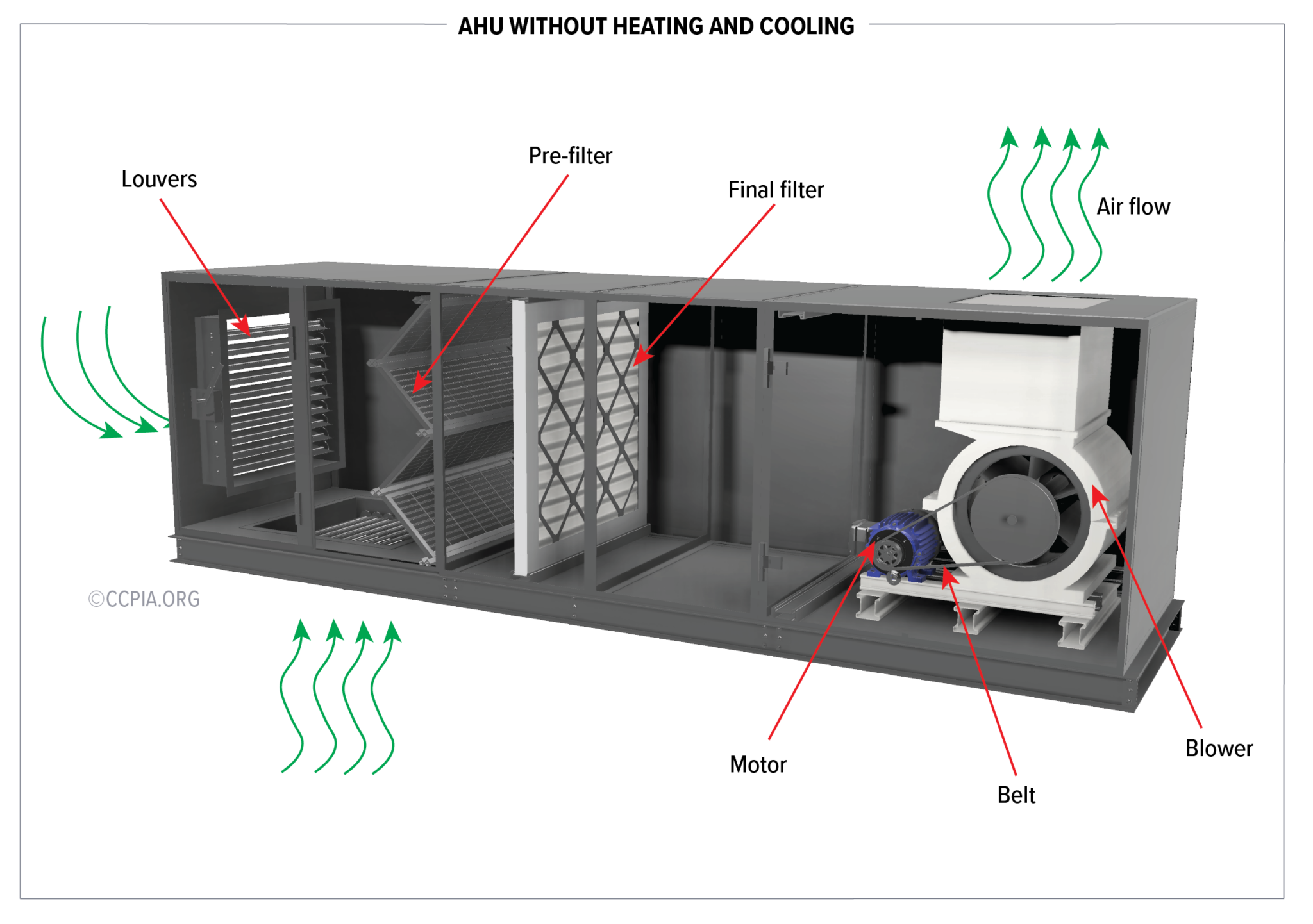

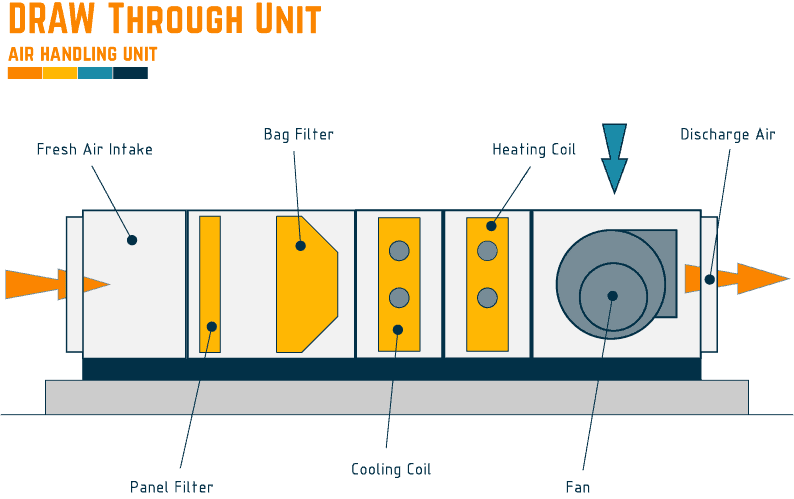

An AHU is comprised of several key components, each performing a specific function:

- Casing: The outer shell that houses all the components, providing structural support and insulation.

- Filters: Remove dust, pollen, and other particulate matter from the air stream. Filter efficiency is rated by MERV (Minimum Efficiency Reporting Value), with higher MERV ratings indicating better filtration. Regular filter replacement is crucial for maintaining air quality and system efficiency.

- Cooling Coil: A heat exchanger that cools the air. Typically, chilled water from a chiller is circulated through the coil, absorbing heat from the air. Alternatively, refrigerant can be directly expanded within the coil.

- Heating Coil: A heat exchanger that heats the air. Similar to cooling coils, heating coils can use hot water or steam from a boiler, or electric resistance heaters.

- Fan: The heart of the AHU, responsible for moving air through the system and into the ductwork. Fans can be either centrifugal or axial, with variable frequency drives (VFDs) often used to control fan speed and airflow.

- Dampers: Adjustable plates that control the amount of outside air and recirculated air entering the AHU. Dampers are crucial for optimizing energy efficiency and maintaining indoor air quality.

- Humidifier: Adds moisture to the air, especially important in dry climates or during winter months. Humidifiers can use steam, water spray, or evaporative methods.

- Dehumidifier: Removes moisture from the air, essential in humid climates. Dehumidifiers often use cooling coils to condense water vapor out of the air.

- Controls: The "brain" of the AHU, monitoring and controlling all the components to maintain desired temperature, humidity, and airflow. Modern AHUs often incorporate sophisticated building automation systems (BAS) for remote monitoring and control.

Types of Air Handling Units

AHUs can be categorized in various ways, based on their configuration, application, and capacity.

- Single-Zone AHUs: These units serve a single zone or area with uniform heating and cooling requirements. They are simpler and less expensive than multi-zone units.

- Multi-Zone AHUs: These units can serve multiple zones with different heating and cooling needs. They use dampers and mixing boxes to deliver air at different temperatures to each zone.

- Make-Up Air Units (MAUs): Specifically designed to bring in fresh outside air to replace air exhausted from the building. MAUs often include heating or cooling coils to condition the incoming air.

- Rooftop Units (RTUs): Self-contained units typically located on the roof of a building, housing all the components of an AHU in a single package. RTUs are common for commercial buildings and offer easy installation and maintenance.

AHU Efficiency and Energy Consumption

The efficiency of an AHU is a critical factor in its operating cost. Several factors influence AHU efficiency:

- Fan Efficiency: High-efficiency fans and VFDs can significantly reduce energy consumption.

- Coil Performance: Clean and properly maintained coils ensure optimal heat transfer.

- Filter Efficiency: While high-MERV filters improve air quality, they also increase airflow resistance, requiring more energy to operate the fan. A balance must be struck between air quality and energy efficiency.

- Control System Optimization: A well-designed and properly programmed control system can optimize AHU operation based on occupancy, weather conditions, and other factors.

- Proper Insulation: Minimizing heat loss or gain through the AHU casing is essential for energy efficiency.

Cost Considerations

The cost of an AHU varies widely depending on its size, features, and application. A small residential AHU might cost a few thousand dollars, while a large commercial AHU can cost tens or even hundreds of thousands of dollars. Installation costs can also be significant, especially for complex systems. Factors affecting cost include:

- Capacity (CFM - Cubic Feet per Minute): Larger AHUs with higher airflow capacity are more expensive.

- Features: Advanced features such as energy recovery, UV sterilization, and sophisticated control systems add to the cost.

- Installation Complexity: Difficult installations requiring extensive ductwork or structural modifications can increase costs.

- Brand Reputation: Well-known and reputable brands often command higher prices.

Maintenance and Lifespan

Regular maintenance is crucial for ensuring the long lifespan and efficient operation of an AHU. Key maintenance tasks include:

- Filter Replacement: Regularly replacing air filters to maintain air quality and system efficiency.

- Coil Cleaning: Cleaning cooling and heating coils to remove dirt and debris that can impede heat transfer.

- Fan Inspection and Maintenance: Inspecting and lubricating fan bearings and motors to ensure smooth operation.

- Damper Inspection and Adjustment: Ensuring dampers are properly adjusted and functioning correctly.

- Control System Calibration: Periodically calibrating the control system to ensure accurate temperature and humidity control.

- Leak Detection and Repair: Identifying and repairing any leaks in the ductwork or AHU casing.

With proper maintenance, an AHU can last for 15-20 years or even longer. Neglecting maintenance can significantly shorten its lifespan and increase operating costs.

Troubleshooting Common AHU Problems

Several common problems can affect AHU performance:

- Insufficient Airflow: Caused by dirty filters, blocked ductwork, or fan malfunctions.

- Temperature Control Issues: Caused by faulty sensors, malfunctioning dampers, or problems with the heating or cooling coils.

- Excessive Noise: Caused by loose components, fan imbalances, or ductwork vibrations.

- Water Leaks: Caused by condensation, pipe leaks, or drain blockages.

- Poor Air Quality: Caused by dirty filters, mold growth, or inadequate ventilation.

Proper diagnosis and repair of these problems are essential for maintaining optimal AHU performance.

Air Handling Units vs. Other HVAC Systems

It's important to distinguish AHUs from other types of HVAC systems. A central air conditioning system typically includes an outdoor condensing unit and an indoor air handler. The air handler in this case is a simpler version of a full AHU, typically consisting of a cooling coil and a fan. In contrast, an AHU can incorporate heating, cooling, humidification, dehumidification, and advanced filtration.

Furnaces are primarily heating systems and do not typically include the same level of air conditioning or filtration capabilities as an AHU.

Chiller-based systems use chillers to produce chilled water, which is then circulated to AHUs throughout the building. This is a common configuration for large commercial buildings.

The Future of Air Handling Units

The future of AHUs is focused on improving energy efficiency, air quality, and control capabilities. Key trends include:

- Energy Recovery Technologies: Utilizing energy recovery wheels or heat exchangers to transfer heat between exhaust air and incoming fresh air, reducing energy consumption.

- Advanced Filtration Systems: Incorporating UV sterilization, activated carbon filters, and other advanced technologies to improve air quality and remove pollutants.

- Smart Controls and IoT Integration: Using advanced sensors, cloud-based analytics, and Internet of Things (IoT) connectivity to optimize AHU performance and provide real-time monitoring and control.

- Modular Design: Developing modular AHUs that can be easily customized and scaled to meet specific building requirements.

By understanding the principles and technologies behind air handling units, homeowners, HVAC technicians, and facility managers can make informed decisions about system selection, operation, and maintenance, ensuring comfortable, healthy, and energy-efficient indoor environments.