What Is A Back Flow Preventer

In the quest for a more sustainable home or business, focusing on HVAC and water systems is crucial. While smart thermostats and energy-efficient furnaces grab headlines, a lesser-known component plays a vital role in both water conservation and energy savings: the backflow preventer. This article will delve into what backflow preventers are, how they work, why they are essential for energy efficiency, and how integrating them with smart home technology can further optimize your resource consumption.

What is a Backflow Preventer?

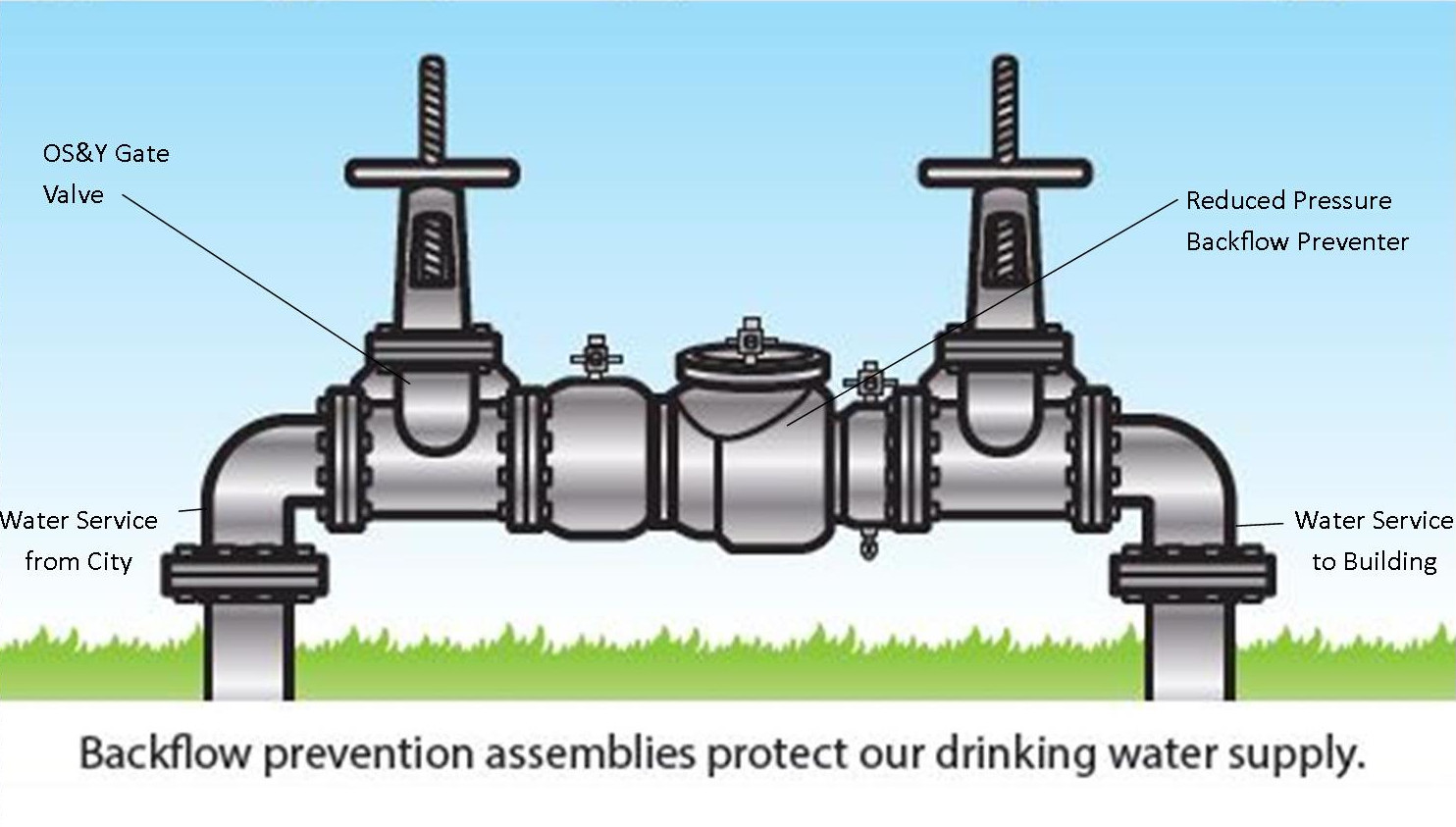

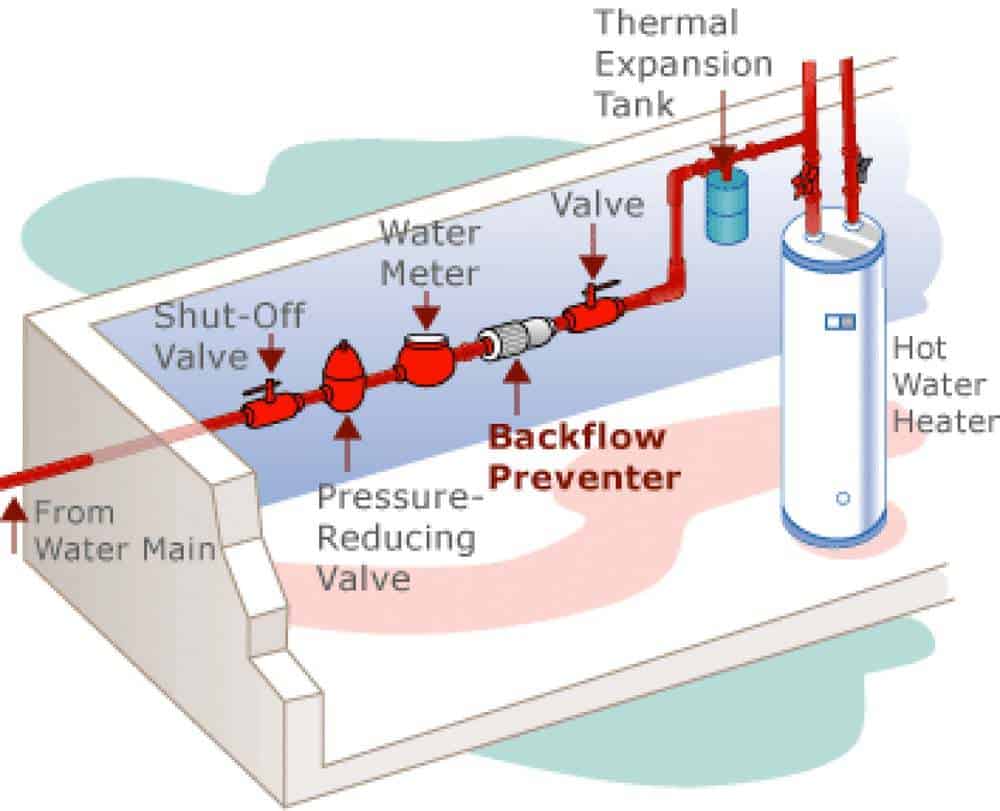

A backflow preventer is a specialized plumbing device designed to prevent contaminated water from flowing backward into the potable (drinking) water supply. Imagine a scenario where water pressure drops in your main water line. This could happen due to a water main break, heavy water usage in your neighborhood, or even firefighting activities. If your plumbing system isn't properly protected, water from your sprinkler system, your swimming pool, or even your toilet could be siphoned back into your drinking water supply. This is known as backflow, and it can have serious health consequences.

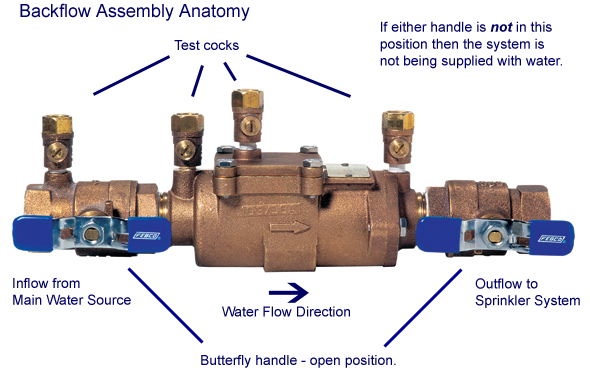

Think of it as a one-way valve that ensures water flows only in the intended direction – from the municipal water supply into your home or business. It is typically installed on water lines that connect to potential sources of contamination, such as irrigation systems, boilers, and fire suppression systems.

How Backflow Preventers Work

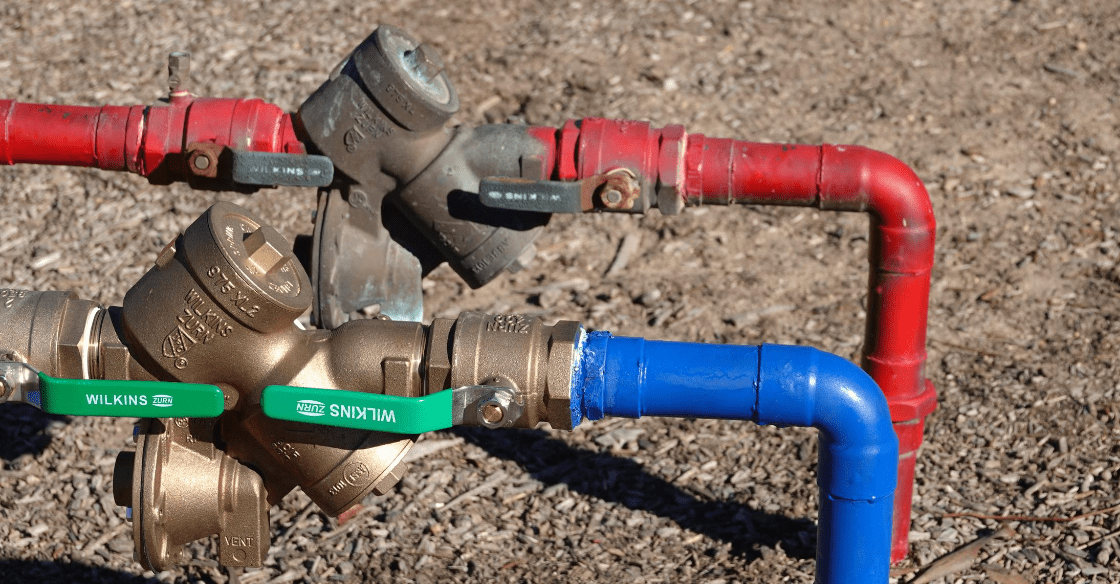

Backflow preventers utilize various mechanical designs to prevent reverse flow. The most common types include:

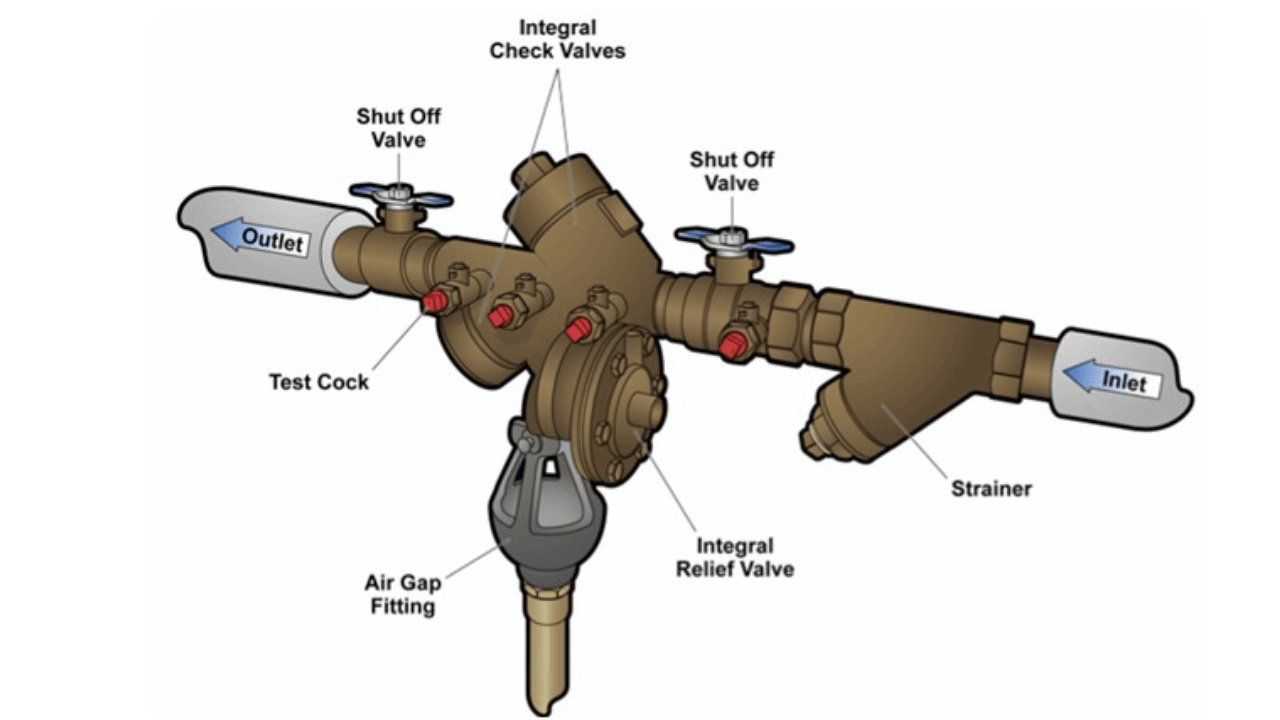

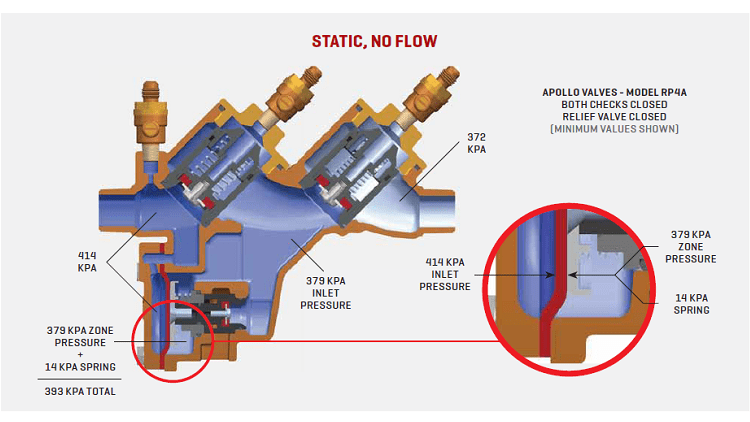

- Reduced Pressure Zone (RPZ) Backflow Preventer: Considered the highest level of protection, an RPZ valve has two independently acting check valves and a pressure-regulated zone between them. If either check valve fails, the reduced pressure zone opens and discharges potentially contaminated water, preventing it from entering the potable water system. RPZ valves are often used in high-hazard situations, such as hospitals and chemical plants.

- Double Check Valve Assembly (DCVA): A DCVA consists of two independently acting spring-loaded check valves. While not as robust as an RPZ valve, it offers a good level of protection for medium-hazard situations, like fire sprinkler systems.

- Pressure Vacuum Breaker (PVB): Commonly used for irrigation systems, a PVB uses a spring-loaded check valve and an air inlet valve. If a vacuum occurs in the water line, the air inlet valve opens, breaking the siphoning action and preventing backflow. However, PVBs must be installed at least 12 inches above the highest point of the irrigation system.

- Atmospheric Vacuum Breaker (AVB): The simplest type of backflow preventer, an AVB is essentially an air gap that prevents backflow. It is typically used for low-hazard applications, such as hose bibs, and must be installed downstream of the last control valve.

The selection of the appropriate backflow preventer depends on the specific application and the level of hazard involved. Local plumbing codes and regulations typically dictate which type of backflow preventer is required for a given situation. Consulting with a licensed plumber is essential to ensure proper installation and compliance.

The Link Between Backflow Prevention and Energy Efficiency

While the primary function of a backflow preventer is to protect the water supply, it indirectly contributes to energy efficiency in several ways:

- Preventing Water Waste: Backflow can lead to water loss if contaminated water is discharged to prevent it from re-entering the potable water system. By properly preventing backflow, you minimize water waste, reducing the demand on municipal water treatment plants, which are energy-intensive operations.

- Optimizing Boiler Efficiency: In commercial buildings and some residential applications, boilers are used for heating. Backflow into the boiler system can introduce impurities that reduce its efficiency and lifespan. By preventing backflow, you maintain the cleanliness of the boiler water, maximizing its heat transfer efficiency and reducing energy consumption. Proper boiler maintenance, including backflow preventer testing, can save up to 10-15% on heating costs, according to the U.S. Department of Energy.

- Protecting HVAC Systems: In chilled water systems used for cooling, backflow can introduce contaminants that corrode pipes and reduce the efficiency of heat exchangers. A backflow preventer safeguards the system, ensuring optimal performance and minimizing energy consumption.

- Reducing Pump Strain: In systems where pumps are used to circulate water (e.g., irrigation systems, cooling towers), backflow can create backpressure, forcing the pump to work harder and consume more energy. A properly functioning backflow preventer minimizes backpressure, reducing pump strain and energy consumption.

Smart HVAC Integration and Backflow Preventers

While backflow preventers are traditionally standalone devices, integrating them with smart home technology can offer even greater energy savings and water conservation benefits.

- Flow Monitoring: Smart flow sensors can be installed on water lines equipped with backflow preventers to monitor water usage in real-time. This allows you to detect leaks and unusual water consumption patterns, which could indicate a backflow issue or a malfunctioning component. Early detection can prevent significant water waste and potential damage to your property.

- Remote Shutoff: In the event of a detected backflow incident, a smart shutoff valve can automatically close the water supply, preventing further contamination and water loss. This is particularly useful for remote properties or situations where immediate manual intervention is not possible.

- Automated Irrigation Control: Smart irrigation controllers can use weather data and soil moisture sensors to optimize watering schedules, minimizing water waste. When combined with a backflow preventer, this ensures that only the necessary amount of water is used, further reducing energy consumption associated with water treatment and distribution. Many smart irrigation controllers are EPA WaterSense certified, ensuring water efficiency.

- Alerts and Notifications: Smart home systems can send alerts and notifications to your smartphone or other devices when a backflow event is detected, or when the backflow preventer requires maintenance or testing. This proactive approach allows you to address potential issues before they escalate into costly problems.

ROI and Rebates

The cost of installing a backflow preventer varies depending on the type of device, the complexity of the installation, and local plumbing codes. However, the long-term benefits in terms of water savings, energy efficiency, and protection of your potable water supply often outweigh the initial investment.

Many municipalities and water utilities offer rebates and incentives for the installation of backflow preventers, particularly for irrigation systems and other water-intensive applications. These rebates can significantly reduce the upfront cost of the device, making it an even more attractive investment. Check with your local water utility and government agencies to see what programs are available in your area.

Moreover, preventing backflow can protect your health and avoid potential fines for violating plumbing codes. Untreated backflow can contain pathogens that cause sickness and disease.

Consider these factors when calculating the ROI of a backflow preventer:

- Water savings: Estimate your potential water savings based on your current water usage and the efficiency of your irrigation system or other water-using equipment.

- Energy savings: Calculate the energy savings associated with reduced water consumption and improved efficiency of boilers and HVAC systems.

- Rebate incentives: Factor in any rebates or incentives offered by your local utility or government agencies.

- Health costs: Consider the risk of waterborne illnesses from backflow.

Maintenance and Testing

Backflow preventers require regular maintenance and testing to ensure they are functioning properly. Most municipalities require annual testing of backflow preventers by a certified technician. This testing involves simulating a backflow condition to verify that the device is effectively preventing reverse flow.

Regular maintenance includes:

- Visual inspection: Check the device for leaks, corrosion, and other signs of damage.

- Cleaning: Remove any debris or sediment that may be obstructing the flow of water.

- Lubrication: Lubricate moving parts as needed to ensure smooth operation.

- Professional Testing: Schedule annual testing by a certified backflow preventer technician.

Keep accurate records of all maintenance and testing activities. This will help you track the performance of your backflow preventer and ensure that it remains in compliance with local regulations.

Conclusion

A backflow preventer is an essential component of any sustainable home or business, protecting the potable water supply and indirectly contributing to energy efficiency. By understanding how backflow preventers work, the different types available, and their integration with smart home technology, you can make informed decisions to optimize your water usage, reduce energy consumption, and create a healthier environment. Don't underestimate the importance of this unassuming device in your quest for a more sustainable future. Consult with a qualified plumber to determine the appropriate backflow preventer for your specific needs and ensure proper installation and maintenance.