What Is A Forced Air Furnace

A forced air furnace is one of the most common types of heating systems used in homes and buildings across North America. It's a reliable and efficient way to distribute warm air throughout a space, providing comfortable temperatures during colder months. Understanding how a forced air furnace works, its components, and its advantages and disadvantages can help you make informed decisions about your heating needs.

What Exactly is a Forced Air Furnace?

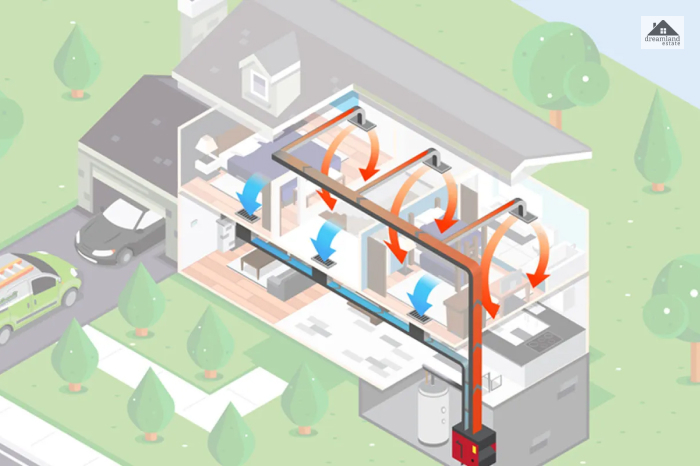

At its core, a forced air furnace is a heating system that uses a central heating unit (the furnace itself) to warm air and then distributes that warm air throughout your home via a network of ducts. The term "forced air" refers to the fact that a blower fan actively pushes the heated air through these ducts, unlike older systems that might rely on gravity or natural convection.

Think of it like this: the furnace is the "heater," the ducts are the "roads," and the blower fan is the "delivery truck" ensuring the heat reaches every room efficiently.

The Key Components of a Forced Air Furnace

To fully understand how a forced air furnace operates, it's essential to know the function of its main components:

1. The Burner

The burner is where the magic (or rather, the heat) happens. This component is responsible for burning fuel to generate heat. Most modern forced air furnaces use natural gas or propane as their fuel source. Older models might use oil. The burner carefully mixes the fuel with air and ignites the mixture to create a controlled flame.

2. The Heat Exchanger

The heat exchanger is a crucial component that separates the combustion gases from the air being circulated into your home. It's typically a series of metal tubes or chambers that are heated by the burner. The air from your home passes over these hot surfaces, absorbing the heat without coming into direct contact with the potentially harmful combustion byproducts. Think of it like a radiator in a car – it gets hot, but the coolant inside (in this case, combustion gases) never mixes with the air outside.

A cracked or damaged heat exchanger can be extremely dangerous, as it can allow carbon monoxide to leak into your home. Carbon monoxide is a colorless, odorless gas that can be fatal. Regular furnace maintenance is vital to ensure the heat exchanger is in good working condition.

3. The Blower Fan

The blower fan, also known as a circulator fan, is the powerhouse that moves the heated air throughout your home. Once the air has been warmed by the heat exchanger, the blower fan pushes it through the ductwork. The blower is typically powered by an electric motor and is controlled by the furnace's control system.

4. The Ductwork

The ductwork is the network of tubes, usually made of sheet metal, that distributes the heated air from the furnace to the various rooms in your home. The ductwork consists of supply ducts, which carry the heated air from the furnace to the registers or vents in each room, and return ducts, which carry the cooler air back to the furnace to be reheated. Proper insulation and sealing of the ductwork are essential for efficient heating, as leaky ducts can result in significant heat loss.

5. The Air Filter

The air filter is a simple but important component that removes dust, pollen, and other particles from the air before it enters the furnace and circulates through your home. A clean air filter helps to improve indoor air quality and also protects the furnace components from becoming clogged with debris. It's recommended to change your air filter every one to three months, depending on the type of filter and the amount of dust and debris in your home.

6. The Thermostat

The thermostat is the control center for your heating system. It senses the temperature in your home and signals the furnace to turn on or off to maintain the desired temperature. Modern thermostats can be programmable, allowing you to set different temperatures for different times of the day or week, which can help to save energy.

7. The Flue

The flue or vent is a pipe that carries the combustion gases (primarily carbon dioxide and water vapor) from the furnace to the outside of your home. It's important to ensure that the flue is properly connected and vented to prevent the buildup of dangerous gases inside your home. The flue must be inspected regularly and kept free of obstructions.

How a Forced Air Furnace Works: A Step-by-Step Guide

Here's a breakdown of how a forced air furnace operates:

- Thermostat Calls for Heat: When the thermostat senses that the temperature in your home is below the setpoint, it sends a signal to the furnace to turn on.

- Ignition: The furnace's control system initiates the ignition sequence. This typically involves opening the gas valve and igniting the fuel using a spark igniter or a pilot light.

- Combustion: The burner mixes the fuel (natural gas or propane) with air and ignites the mixture, creating a flame that heats the heat exchanger.

- Heat Exchange: The air from your home is drawn into the furnace and passes over the hot heat exchanger, absorbing the heat. The combustion gases are safely vented to the outside through the flue.

- Air Circulation: The blower fan kicks on and pushes the heated air through the supply ducts and into the rooms of your home.

- Return Air: As the heated air cools down, it returns to the furnace through the return ducts.

- Cycle Repeats: The furnace continues to cycle on and off as needed to maintain the desired temperature set on the thermostat.

Advantages of Forced Air Furnaces

Forced air furnaces offer several advantages, making them a popular choice for home heating:

- Efficient Heating: Forced air furnaces can quickly and efficiently heat a large space.

- Even Heat Distribution: The ductwork system allows for relatively even distribution of heat throughout the home.

- Relatively Low Cost: Forced air furnaces are generally less expensive to install and maintain compared to other types of heating systems, such as radiant heating.

- Versatility: The same ductwork can be used for both heating and air conditioning, making it easy to integrate a central air conditioning system.

- Air Filtration: The air filter helps to improve indoor air quality by removing dust and other particles from the air.

Disadvantages of Forced Air Furnaces

Despite their advantages, forced air furnaces also have some drawbacks:

- Ductwork Required: The need for ductwork can be a limitation in some homes, particularly older homes that were not originally designed for forced air systems.

- Noise: The blower fan can be noisy, especially in older models.

- Dry Air: Forced air heating can dry out the air, leading to discomfort and potential health problems. Using a humidifier can help to alleviate this issue.

- Potential for Dust Circulation: While the air filter helps to remove dust, some dust and allergens can still circulate through the ductwork.

- Maintenance Required: Regular maintenance, including changing the air filter and inspecting the furnace, is essential to ensure optimal performance and prevent problems.

Choosing the Right Forced Air Furnace

Selecting the right forced air furnace for your home depends on several factors, including the size of your home, your climate, and your budget. Here are some key considerations:

- BTU Rating: The BTU (British Thermal Unit) rating of a furnace indicates its heating capacity. The appropriate BTU rating for your home depends on its size, insulation, and climate. A heating contractor can help you determine the correct BTU rating for your needs.

- AFUE Rating: The AFUE (Annual Fuel Utilization Efficiency) rating measures the furnace's energy efficiency. The higher the AFUE rating, the more efficient the furnace is. Modern furnaces typically have AFUE ratings of 80% or higher. Look for Energy Star certified models for maximum efficiency.

- Fuel Type: The most common fuel types for forced air furnaces are natural gas and propane. The choice of fuel depends on its availability in your area and its cost.

- Variable-Speed Blower: A variable-speed blower can improve energy efficiency and comfort by adjusting the airflow based on the heating demand.

Maintenance Tips for Forced Air Furnaces

Proper maintenance is essential for keeping your forced air furnace running efficiently and safely. Here are some tips:

- Change the Air Filter Regularly: This is the most important maintenance task. Check the filter every month and replace it every one to three months, depending on the type of filter and the amount of dust in your home.

- Schedule Annual Inspections: Have a qualified HVAC technician inspect your furnace annually. They can clean the burner, check the heat exchanger, and ensure that all components are functioning properly.

- Keep the Area Around the Furnace Clear: Ensure that there is plenty of space around the furnace for proper ventilation and access.

- Consider a Programmable Thermostat: A programmable thermostat can help you save energy by automatically adjusting the temperature when you are away from home or asleep.

Safety Precautions

Forced air furnaces can be safe and reliable when properly maintained, but it's important to take certain safety precautions:

- Carbon Monoxide Detectors: Install carbon monoxide detectors in your home and test them regularly.

- Never Block Vents: Do not block the supply or return vents, as this can reduce the efficiency of the heating system and create a fire hazard.

- Do Not Store Flammable Materials Near the Furnace: Keep flammable materials, such as gasoline and paint, away from the furnace.

- Call a Professional for Repairs: Do not attempt to repair your furnace yourself unless you are a qualified HVAC technician.

By understanding how a forced air furnace works, its components, and its maintenance requirements, you can make informed decisions about your heating needs and ensure that your system operates safely and efficiently for years to come. Remember that regular maintenance and professional inspections are key to maximizing the lifespan and performance of your forced air furnace.