What Is A Heat Recovery Ventilator

What is a Heat Recovery Ventilator (HRV)? A Comprehensive Guide

In today's energy-conscious world, maintaining a comfortable indoor environment without exorbitant energy bills is a top priority for homeowners, property managers, and facility engineers alike. One technology gaining significant traction in this area is the Heat Recovery Ventilator (HRV). But what exactly is an HRV, and how does it work? This article provides a detailed overview, breaking down the technology, its benefits, applications, and considerations for installation and maintenance.

Understanding the Basics: Ventilation and Air Quality

Before diving into the specifics of HRVs, it's essential to understand the fundamental principle of ventilation. Buildings naturally accumulate stale air, containing pollutants like dust, volatile organic compounds (VOCs) from cleaning products and furniture, and excess moisture. Adequate ventilation is crucial for replacing this stale air with fresh, outdoor air, thereby improving indoor air quality (IAQ) and safeguarding the health of occupants.

Traditional ventilation methods, such as opening windows, while effective, are energy inefficient. They allow conditioned (heated or cooled) air to escape, forcing your HVAC system to work harder to maintain the desired temperature. This is where the HRV comes into play.

How HRVs Work: Recovering Heat, Saving Energy

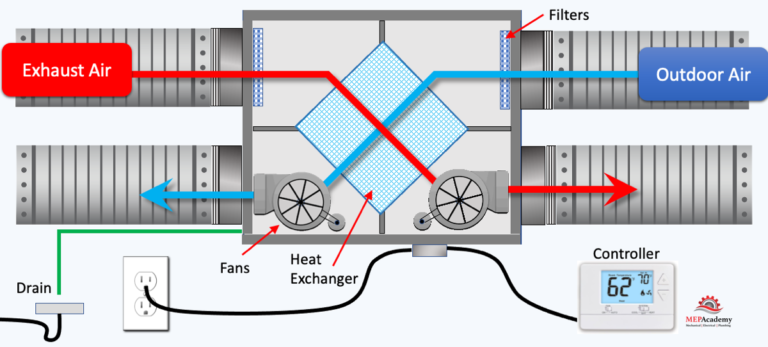

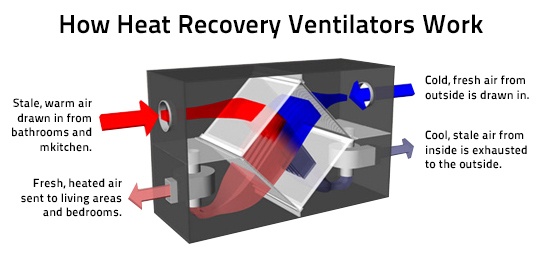

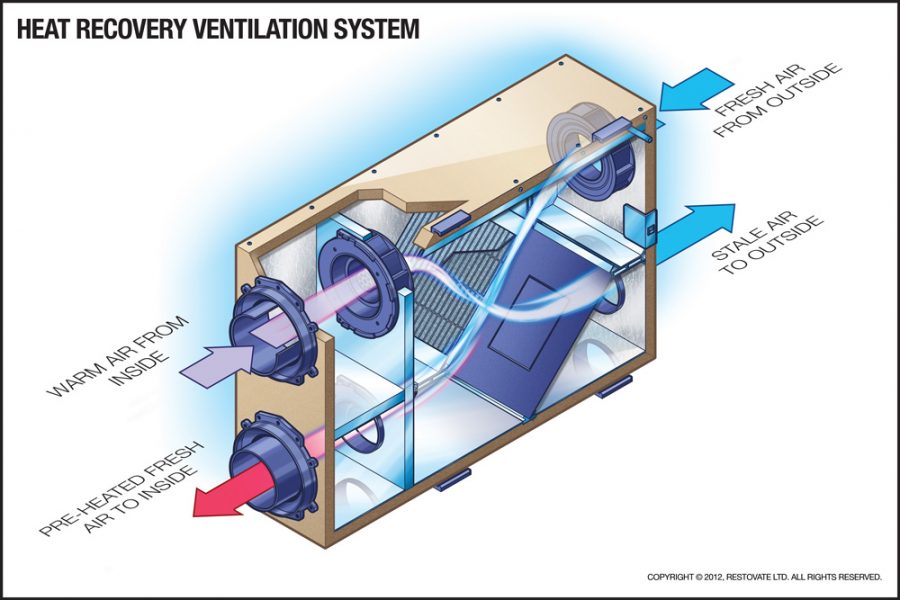

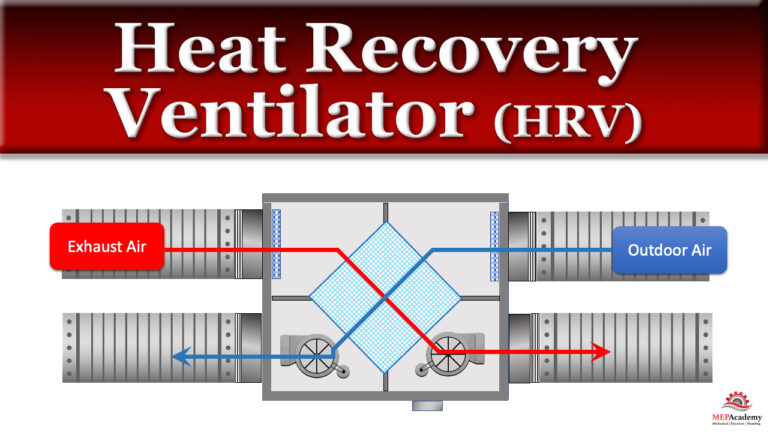

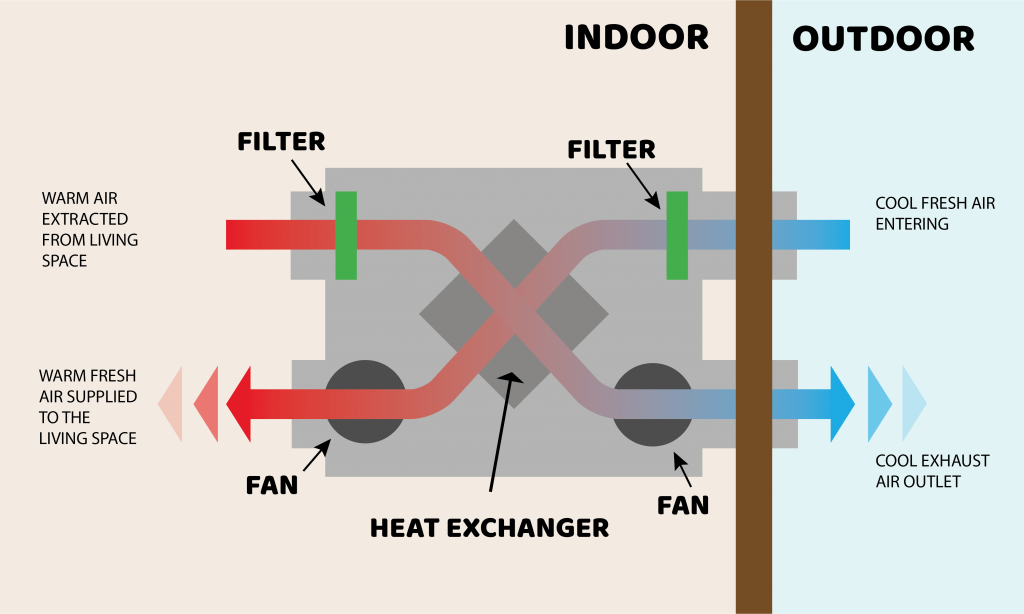

An HRV is a mechanical ventilation system that recovers heat energy from exhaust air and uses it to pre-heat or pre-cool incoming fresh air. Imagine it as a sophisticated air exchanger with a built-in energy recovery system. Here's a breakdown of the process:

- Exhaust Air Stream: Stale, warm (in winter) or cool (in summer) air is extracted from areas like bathrooms, kitchens, and laundry rooms, where moisture and pollutants are concentrated.

- Fresh Air Intake: Simultaneously, fresh outdoor air is drawn into the HRV unit.

- Heat Exchanger Core: The key component of the HRV is the heat exchanger core. This core, made of materials like aluminum or plastic, facilitates heat transfer between the two air streams without mixing them. In winter, the warm exhaust air heats the incoming cold air. In summer, the cool exhaust air pre-cools the hot incoming air.

- Filtered Air Delivery: The pre-heated or pre-cooled fresh air is then distributed throughout the building, typically through the existing ductwork or a dedicated ventilation system.

- Exhaust to Outdoors: The cooled (in winter) or heated (in summer) exhaust air is expelled outside.

This process significantly reduces the energy required to heat or cool the incoming fresh air, leading to substantial energy savings.

Types of Heat Exchangers

Several types of heat exchangers are used in HRVs, each with its own advantages and disadvantages:

- Plate Heat Exchangers: These are the most common type, consisting of a series of thin plates separated by narrow air passages. They offer good heat transfer efficiency and are relatively inexpensive.

- Rotary Heat Exchangers (Energy Recovery Wheels): These exchangers utilize a rotating wheel with a porous material that absorbs heat from one air stream and releases it to the other. Rotary exchangers can also transfer moisture, which can be beneficial in dry climates. They are often referred to as Energy Recovery Ventilators (ERVs), discussed below.

- Heat Pipe Heat Exchangers: These use a sealed pipe containing a refrigerant that evaporates in the warm air stream and condenses in the cold air stream, transferring heat in the process.

HRV vs. ERV: Understanding the Difference

While often used interchangeably, HRVs and Energy Recovery Ventilators (ERVs) differ in their ability to manage moisture. HRVs primarily transfer heat, while ERVs transfer both heat and moisture. This makes ERVs a better choice for climates with high humidity, as they can help prevent excessive dryness in winter and maintain comfortable humidity levels in summer. In contrast, HRVs are often preferred in colder, drier climates.

The key difference lies in the heat exchanger core. ERVs utilize cores coated with a desiccant material that absorbs moisture from the more humid air stream and releases it to the drier air stream.

Benefits of Installing an HRV

The benefits of HRV installation are numerous and extend beyond just energy savings:

- Improved Indoor Air Quality: HRVs continuously introduce fresh, filtered air, reducing indoor pollutants and allergens.

- Energy Savings: By recovering heat, HRVs reduce the load on your heating and cooling systems, leading to lower energy bills. Estimates vary, but savings of 15-30% on heating costs are common in colder climates.

- Moisture Control: HRVs can help control humidity levels, preventing condensation and mold growth (ERVs are even better at this).

- Reduced Drafts: HRVs provide controlled ventilation, minimizing drafts and maintaining a more consistent temperature throughout the building.

- Increased Home Value: Installing an HRV can increase the value of your home, as it demonstrates a commitment to energy efficiency and indoor air quality.

Applications of HRVs

HRVs are suitable for a wide range of applications, including:

- Residential Homes: HRVs are particularly beneficial in tightly sealed homes, where natural ventilation is limited.

- Apartment Buildings: Multi-unit dwellings can benefit from centralized or decentralized HRV systems.

- Commercial Buildings: Offices, schools, and hospitals can utilize HRVs to improve IAQ and reduce energy consumption.

- Industrial Facilities: HRVs can be used to recover heat from industrial processes, further enhancing energy efficiency.

Installation and Maintenance

HRV installation typically involves connecting the unit to the existing ductwork or installing a dedicated ventilation system. It's crucial to hire a qualified HVAC technician to ensure proper installation and sizing of the HRV. Incorrect installation can lead to reduced performance or even damage to the system.

Regular maintenance is also essential for maintaining optimal performance. This includes:

- Filter Replacement: Replace air filters every 1-3 months, depending on air quality and usage. Dirty filters reduce airflow and efficiency.

- Core Cleaning: Clean the heat exchanger core annually or as needed. Refer to the manufacturer's instructions for cleaning procedures.

- Duct Cleaning: Periodically clean the ductwork to remove dust and debris.

- Professional Inspection: Schedule an annual inspection by a qualified HVAC technician to ensure proper operation and identify any potential issues.

Cost, Efficiency, and Lifespan

The cost of an HRV system varies depending on its size, features, and installation complexity. A basic HRV for a typical home can range from $500 to $2,000 for the unit itself, with installation costs adding another $500 to $1,500. More complex systems for larger buildings can cost significantly more.

The efficiency of an HRV is measured by its Sensible Recovery Efficiency (SRE), which indicates the percentage of heat that is recovered from the exhaust air. SRE values typically range from 50% to 85%. The higher the SRE, the more energy you save.

A well-maintained HRV can last for 15-20 years. Proper maintenance, including regular filter replacement and core cleaning, is crucial for extending the lifespan of the system.

Making the Right Choice

Choosing the right HRV system depends on several factors, including climate, building size, and budget. Consider the following:

- Climate: If you live in a humid climate, an ERV may be a better choice than an HRV.

- Building Size: Select an HRV with the appropriate airflow capacity for your building size. Oversized units can be inefficient, while undersized units may not provide adequate ventilation.

- Air Quality: Consider the level of air filtration required based on the air quality in your area.

- Noise Level: Look for units with low noise levels to minimize disruption.

- Features: Some HRVs offer advanced features like variable speed fans, automatic defrost, and remote control.

Consulting with a qualified HVAC professional is highly recommended to determine the best HRV system for your specific needs. They can assess your building's ventilation requirements, recommend suitable models, and ensure proper installation.

Conclusion

A heat recovery ventilator is a valuable investment for homeowners and property managers seeking to improve indoor air quality, reduce energy consumption, and create a more comfortable living or working environment. By understanding the technology, its benefits, and considerations for installation and maintenance, you can make an informed decision and reap the rewards of this energy-efficient ventilation solution.