What Is A Water Source Heat Pump

Welcome to the world of Water Source Heat Pumps (WSHPs)! Whether you're a homeowner exploring eco-friendly heating and cooling options, an HVAC technician looking to expand your knowledge, or a property manager responsible for maintaining a large building's climate control, this comprehensive guide will provide a detailed overview of WSHPs. We'll delve into what they are, how they work, their advantages, disadvantages, applications, and more.

What is a Water Source Heat Pump?

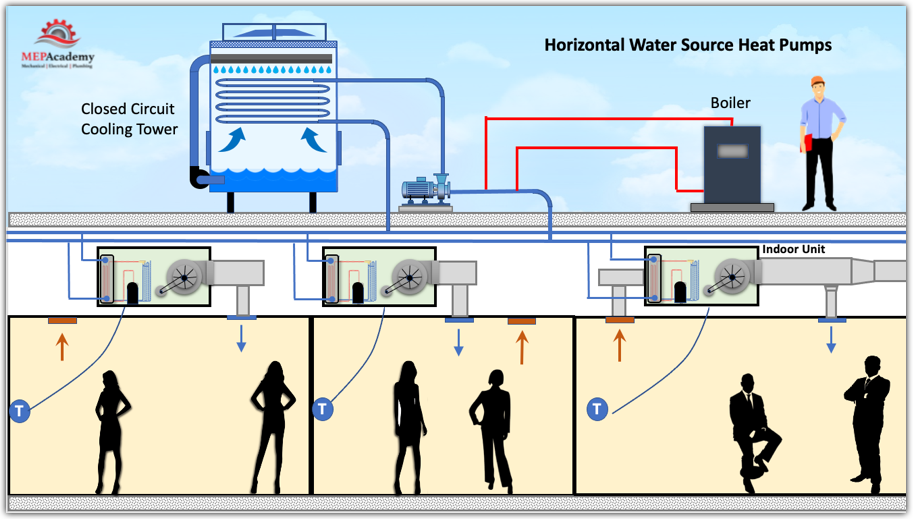

At its core, a Water Source Heat Pump (WSHP) is a type of geothermal heat pump that uses water as the heat exchange medium. Unlike air source heat pumps that exchange heat with the outside air, WSHPs utilize a closed-loop piping system filled with water (often treated with antifreeze) to transfer heat between the building and a central water loop. This loop maintains a relatively constant temperature throughout the year, typically between 60°F and 90°F (15°C and 32°C), providing a stable source for both heating and cooling.

Think of it like this: imagine a building with many individual heat pump units. Each unit can either extract heat from the water loop to warm its zone or reject heat into the water loop to cool its zone. The loop acts as a thermal reservoir, allowing units operating in heating mode to help provide heat for units operating in cooling mode, significantly improving overall energy efficiency.

How Water Source Heat Pumps Work

The basic working principle of a WSHP revolves around the refrigeration cycle, which is used in most cooling and heating devices. The components include a compressor, condenser, expansion valve, and evaporator. Let's break it down:

- Heating Mode: In heating mode, the heat pump extracts heat from the water loop (even relatively cool water contains usable heat). The refrigerant absorbs this heat in the evaporator and evaporates into a gas.

- Compression: The gaseous refrigerant is then compressed by the compressor, raising its temperature and pressure.

- Condensation: The hot, high-pressure refrigerant flows through the condenser, where it releases heat to the indoor air. This heats the building space, and the refrigerant condenses back into a liquid.

- Expansion: The liquid refrigerant then passes through an expansion valve, which reduces its pressure and temperature.

- Cycle Repeats: The cool, low-pressure refrigerant returns to the evaporator to start the cycle again.

In cooling mode, the process is reversed. The heat pump extracts heat from the indoor air and transfers it to the water loop. This is achieved by reversing the flow of refrigerant using a reversing valve. The refrigerant absorbs heat from the indoor air in the evaporator, cools and dehumidifies the space. The heat is then rejected into the water loop through the condenser.

A crucial component is the boiler and cooling tower system, which is vital for maintaining the temperature of the water loop. If the overall building requires more heating than cooling, the boiler adds heat to the loop. Conversely, if more cooling is required, the cooling tower rejects excess heat into the atmosphere. These components ensure that the water loop remains within the optimal temperature range for efficient operation of the WSHPs.

Types of Water Source Heat Pump Systems

Several types of WSHP systems exist, each suited for different applications:

- Centralized WSHP Systems: These systems use a single, large central plant to heat and cool an entire building or complex. They are typically used in large commercial buildings, hospitals, and universities.

- Decentralized WSHP Systems: These systems use individual heat pump units located throughout the building. Each unit serves a specific zone or area, allowing for greater individual control. They are commonly used in apartment buildings, condominiums, and office buildings.

- Geothermal WSHP Systems: These systems utilize the earth's stable underground temperature as the heat source and sink. They are connected to a ground loop, which is a network of pipes buried in the ground. Geothermal systems offer the highest efficiency and lowest operating costs but require a significant upfront investment.

Advantages of Water Source Heat Pumps

WSHPs offer numerous advantages over traditional HVAC systems:

- High Efficiency: WSHPs are significantly more energy-efficient than traditional furnaces and air conditioners. Their Coefficient of Performance (COP), a measure of heating efficiency, can range from 3.0 to 5.0, meaning they produce 3 to 5 units of heat for every unit of electricity consumed. Similarly, their Energy Efficiency Ratio (EER), a measure of cooling efficiency, can range from 10 to 20.

- Individual Zone Control: Decentralized WSHP systems allow for individual zone control, meaning that each room or area can be heated or cooled to its own desired temperature.

- Simultaneous Heating and Cooling: WSHPs can provide simultaneous heating and cooling, which is especially beneficial in buildings with different zones that have different heating and cooling needs. For instance, a south-facing office may require cooling even on a winter day, while a north-facing office may require heating.

- Reduced Operating Costs: Due to their high efficiency, WSHPs can significantly reduce operating costs compared to traditional HVAC systems.

- Environmentally Friendly: WSHPs use a renewable energy source (the earth or water) and reduce greenhouse gas emissions compared to fossil fuel-based heating systems.

- Long Lifespan: With proper maintenance, WSHPs can last for 20 years or more, which is longer than the lifespan of many traditional HVAC systems.

Disadvantages of Water Source Heat Pumps

While WSHPs offer many benefits, there are also some disadvantages to consider:

- High Initial Cost: The initial cost of installing a WSHP system can be higher than that of a traditional HVAC system, especially for geothermal systems.

- Complexity of Installation: WSHP systems can be more complex to install than traditional HVAC systems, requiring specialized expertise.

- Water Loop Maintenance: The water loop requires regular maintenance to prevent corrosion, scaling, and biological growth.

- Potential for Leaks: Leaks in the water loop can cause water damage and require costly repairs.

- Reliance on Water Source: The system relies on a reliable water source or ground loop, which may not be available in all locations.

Applications of Water Source Heat Pumps

WSHPs are suitable for a wide range of applications, including:

- Residential Buildings: WSHPs can be used in single-family homes, apartments, and condominiums.

- Commercial Buildings: WSHPs are commonly used in office buildings, retail stores, and restaurants.

- Institutional Buildings: WSHPs are often used in schools, hospitals, and universities.

- Industrial Buildings: WSHPs can be used in factories, warehouses, and manufacturing plants.

Cost, Efficiency Ratings, and Lifespan

Cost: The installed cost of a WSHP system can vary depending on the size and complexity of the system, the type of heat source (water well, ground loop, etc.), and the location. A typical residential WSHP system can cost anywhere from $3,000 to $10,000 per ton (12,000 BTU/hr). Geothermal systems typically have a higher upfront cost than water source systems that use a cooling tower or boiler system.

Efficiency Ratings: As mentioned earlier, WSHPs are highly efficient. Their efficiency is measured by COP (Coefficient of Performance) for heating and EER (Energy Efficiency Ratio) for cooling. Look for units with high COP and EER ratings to maximize energy savings.

Lifespan: The lifespan of a WSHP system can range from 15 to 25 years, depending on the quality of the equipment, the maintenance practices, and the operating conditions. Regular maintenance, such as cleaning coils, inspecting for leaks, and maintaining proper water chemistry, can extend the lifespan of the system.

Maintenance Tips for Water Source Heat Pumps

Proper maintenance is crucial for ensuring the efficient and reliable operation of your WSHP system. Here are some essential maintenance tips:

- Regular Inspections: Schedule regular inspections by a qualified HVAC technician to identify and address any potential problems early on.

- Filter Cleaning/Replacement: Clean or replace air filters regularly (typically every 1-3 months) to maintain optimal airflow and efficiency.

- Coil Cleaning: Clean the evaporator and condenser coils regularly to remove dirt and debris that can reduce heat transfer efficiency.

- Water Loop Maintenance: Maintain proper water chemistry in the water loop to prevent corrosion, scaling, and biological growth. This may involve adding chemicals to the water and periodically flushing the loop.

- Leak Detection: Regularly inspect the water loop for leaks and repair any leaks promptly to prevent water damage and efficiency losses.

- Professional Servicing: Have a qualified HVAC technician perform annual servicing of the system, including checking the refrigerant charge, inspecting the compressor and other components, and calibrating controls.

Conclusion

Water Source Heat Pumps are an efficient, environmentally friendly, and versatile heating and cooling solution suitable for a wide range of applications. While the initial cost may be higher than that of traditional HVAC systems, the long-term benefits, such as reduced operating costs, improved energy efficiency, and individual zone control, make them a worthwhile investment. Whether you're a homeowner, HVAC technician, or property manager, understanding the principles and advantages of WSHPs can help you make informed decisions about your heating and cooling needs.