What Is Difference Between Schedule 40 And 80 Pvc

Understanding the nuances of PVC piping is crucial for many home improvement and HVAC projects. Two of the most common types are Schedule 40 and Schedule 80 PVC. While they might look similar, their differences in construction, pressure ratings, and applications can significantly impact your project's success and safety. Choosing the right type of PVC pipe is vital for a long-lasting and efficient system, especially when dealing with HVAC drainage and ventilation.

Decoding Schedule 40 PVC

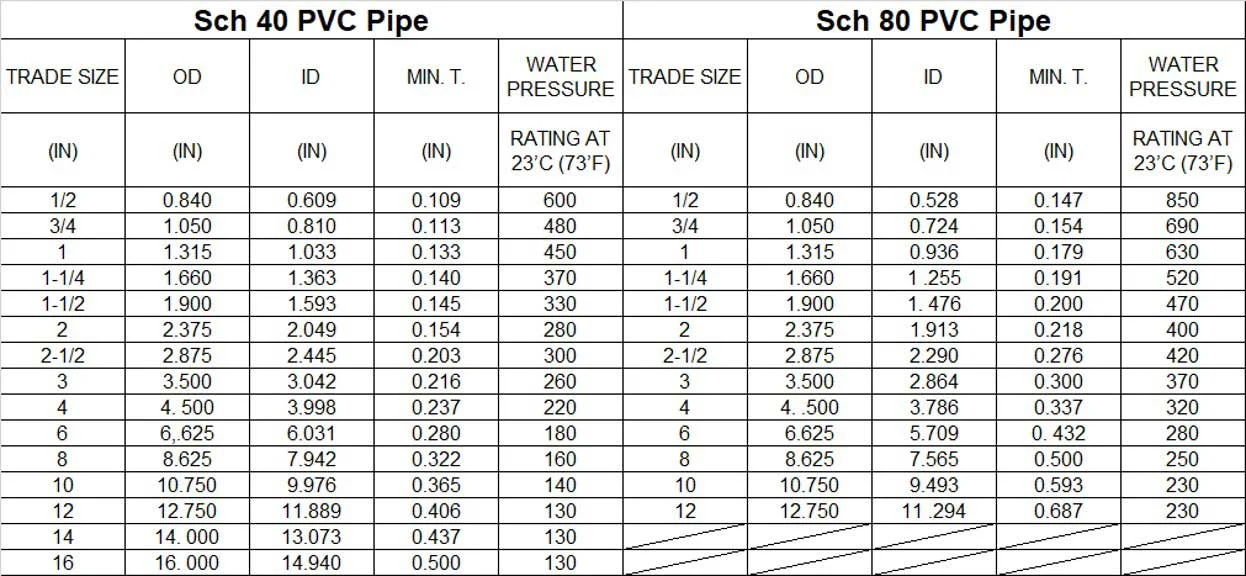

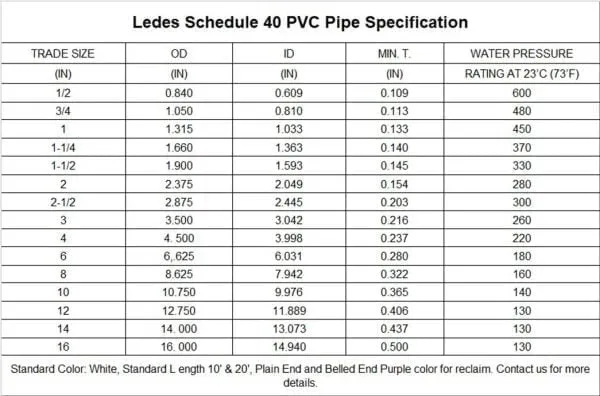

Schedule 40 PVC is the more common and widely used type of PVC pipe, especially in residential settings. It's known for its versatility and affordability. But what exactly makes it "Schedule 40"? The "schedule" number refers to the wall thickness of the pipe. A higher schedule number means a thicker wall.

Key Characteristics of Schedule 40 PVC

- Wall Thickness: Schedule 40 PVC has a thinner wall compared to Schedule 80.

- Pressure Rating: Lower pressure rating, typically suitable for residential plumbing and drainage.

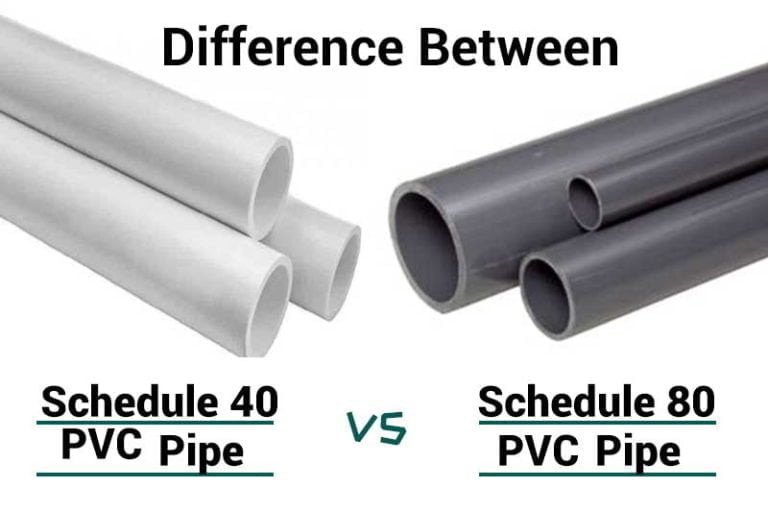

- Color: Usually white or light gray.

- Cost: Generally less expensive than Schedule 80.

- Applications: Primarily used for drain, waste, and vent (DWV) systems, irrigation, and low-pressure water distribution. Also, sometimes used in HVAC condensate drains.

Common Applications in HVAC

Within HVAC systems, Schedule 40 PVC is often used for:

- Condensate Drains: Draining condensation from air conditioners, furnaces, and other HVAC equipment.

- Ventilation: Occasionally for low-pressure ventilation systems, but less common than other materials like ductwork.

Safety Tip: Always check local codes and regulations before using PVC in any application. Ensure the chosen pipe is rated for the specific pressures and temperatures it will encounter.

Exploring Schedule 80 PVC

Schedule 80 PVC is the heavyweight champion of PVC pipes. Its thicker wall makes it significantly stronger and more resistant to pressure and temperature changes compared to Schedule 40.

Key Characteristics of Schedule 80 PVC

- Wall Thickness: Thicker wall compared to Schedule 40, offering greater strength and durability.

- Pressure Rating: Higher pressure rating, suitable for industrial and commercial applications, and situations with higher fluid pressures.

- Color: Typically dark gray, making it easily distinguishable from Schedule 40.

- Cost: More expensive than Schedule 40 due to the increased material and manufacturing costs.

- Applications: Used in chemical processing, industrial applications, pressurized water systems, and applications requiring higher temperature resistance.

When to Consider Schedule 80 in HVAC

While less common than Schedule 40, Schedule 80 PVC might be preferred in specific HVAC scenarios:

- High-Pressure Systems: If the HVAC system involves fluids under high pressure, Schedule 80 provides a safety margin.

- Harsh Chemical Environments: If the pipe will be exposed to corrosive chemicals, Schedule 80's increased chemical resistance can be beneficial.

- Areas with Potential for Physical Damage: The thicker wall of Schedule 80 offers greater protection against impacts and abrasions.

Warning: Working with high-pressure systems can be dangerous. Incorrectly installed or inadequate piping can lead to leaks, bursts, and potential injuries. Always consult with a qualified HVAC professional for installations involving high pressures or hazardous materials.

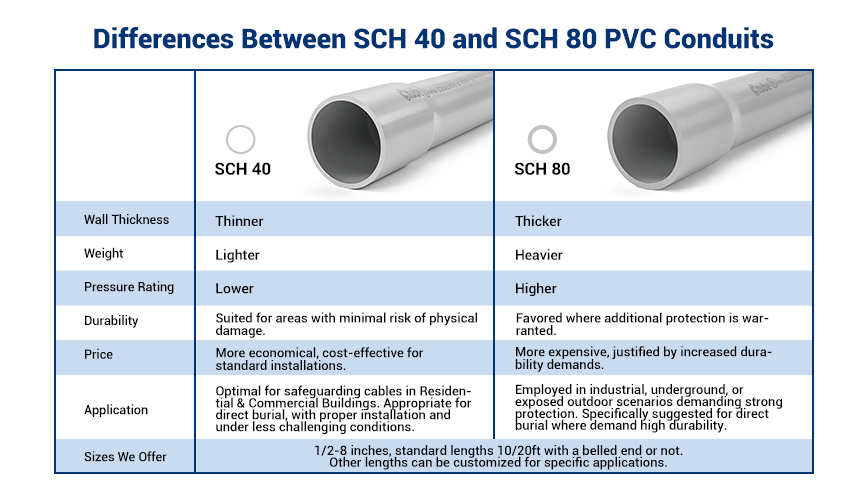

Schedule 40 vs. Schedule 80: A Head-to-Head Comparison

To clearly illustrate the differences, here's a side-by-side comparison:

| Feature | Schedule 40 PVC | Schedule 80 PVC |

|---|---|---|

| Wall Thickness | Thinner | Thicker |

| Pressure Rating | Lower | Higher |

| Color | White or Light Gray | Dark Gray |

| Cost | Lower | Higher |

| Typical Applications | DWV, Irrigation, Condensate Drains | Industrial, Chemical Processing, Pressurized Systems |

DIY Considerations and Potential Pitfalls

While some PVC projects are suitable for DIY enthusiasts, it's crucial to understand your limitations and prioritize safety. Here's a breakdown of tasks you might consider handling yourself and when to call a professional.

DIY-Friendly Tasks

- Replacing Sections of Existing Condensate Drain Lines: If you're comfortable cutting and gluing PVC, replacing a damaged section of a condensate drain line can be a straightforward task. Important: Ensure the new section is the same type (Schedule 40) and size as the existing pipe.

- Minor Adjustments to Existing PVC Piping: Small adjustments, like repositioning a drain line slightly, can often be done with basic tools.

When to Call a Professional

- Complex HVAC System Modifications: Any modifications to the main HVAC system, including ductwork or refrigerant lines, should be left to qualified technicians.

- High-Pressure Applications: As mentioned earlier, high-pressure systems require specialized knowledge and equipment.

- Suspected Leaks or Damage Within Walls or Ceilings: Hidden leaks can cause significant damage. A professional can locate and repair them efficiently.

- Any Task You're Uncomfortable With: If you're unsure about any aspect of the project, it's always best to err on the side of caution and seek professional assistance.

Tools You'll Need for PVC Work

- PVC Cutter: For clean, straight cuts.

- PVC Primer and Cement: For creating a strong, watertight bond.

- Measuring Tape: For accurate measurements.

- Safety Glasses: To protect your eyes from debris.

- Gloves: To protect your hands from primer and cement.

Common Problems and Solutions

- Leaking Joints: Ensure the pipe is properly cleaned, primed, and cemented. Allow sufficient drying time.

- Clogged Drain Lines: Regularly flush condensate drain lines with vinegar or a commercial drain cleaner.

- Sagging Pipes: Use proper supports to prevent pipes from sagging, which can lead to drainage issues.

Cost Considerations

The cost of PVC projects varies depending on the scope of the work, the materials used, and whether you hire a professional. Here's a general idea of potential costs:

- DIY Materials: A small PVC repair might cost between $10 and $50 for materials like pipe, fittings, primer, and cement.

- Professional Repair: Hiring a professional for a simple repair could range from $75 to $200, depending on the complexity and the contractor's rates.

- Larger Projects: More extensive projects, such as replacing a significant portion of your drainage system, could cost several hundred to several thousand dollars.

Tip: Always get multiple quotes from different contractors before hiring someone for a larger project. Be sure to ask for a detailed breakdown of the costs involved.

Final Thoughts

Choosing between Schedule 40 and Schedule 80 PVC is crucial for the success and safety of your projects. While Schedule 40 is generally suitable for residential HVAC condensate drains and other low-pressure applications, Schedule 80 offers superior strength and pressure resistance for more demanding situations. By understanding the differences and following proper installation techniques, you can ensure a long-lasting and reliable system. Always prioritize safety and don't hesitate to consult a qualified professional when needed.