What Is The Ice Exam In Hvac

The term "ICE exam" in the HVAC context isn't a standardized industry certification or test like the EPA Section 608 certification for handling refrigerants or NATE certification. Instead, "ICE" often refers to a more general, informal assessment of an HVAC system's overall performance, particularly focusing on its Internal Condition and Efficiency. This isn't a single, rigidly defined procedure, but rather a comprehensive evaluation undertaken by HVAC professionals to diagnose issues, optimize performance, and ensure the longevity of the equipment.

Understanding the Scope of an "ICE" Evaluation

While not an official certification, an "ICE exam" (or simply an ICE check) can encompass several crucial aspects of an HVAC system. It's a holistic approach that looks beyond just whether the system is currently heating or cooling effectively. It dives into the mechanics, electrical components, and environmental factors that contribute to its long-term health.

Key Components of an Internal Condition and Efficiency (ICE) Examination

Here's a breakdown of what an HVAC technician might examine during a comprehensive "ICE" evaluation:

- Refrigerant Levels and Leaks: This is paramount. Incorrect refrigerant levels drastically reduce efficiency and can damage the compressor. Technicians use gauges and electronic leak detectors to identify leaks and ensure the system is properly charged. Imagine a car engine running with low oil – similar damage can occur in an HVAC system.

- Compressor Health: The compressor is the heart of the cooling system. The technician will assess its operating temperature, amperage draw, and overall sound to identify potential problems. Unusual noises, excessive heat, or high amperage readings can indicate a failing compressor.

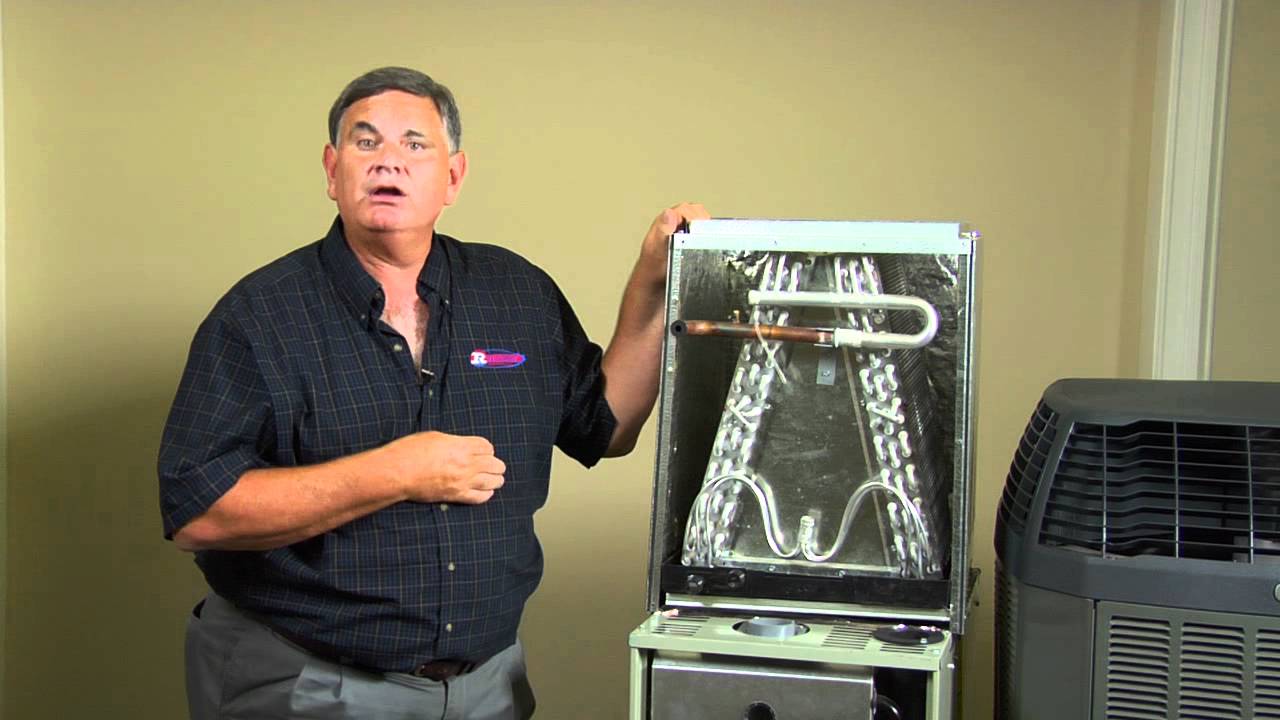

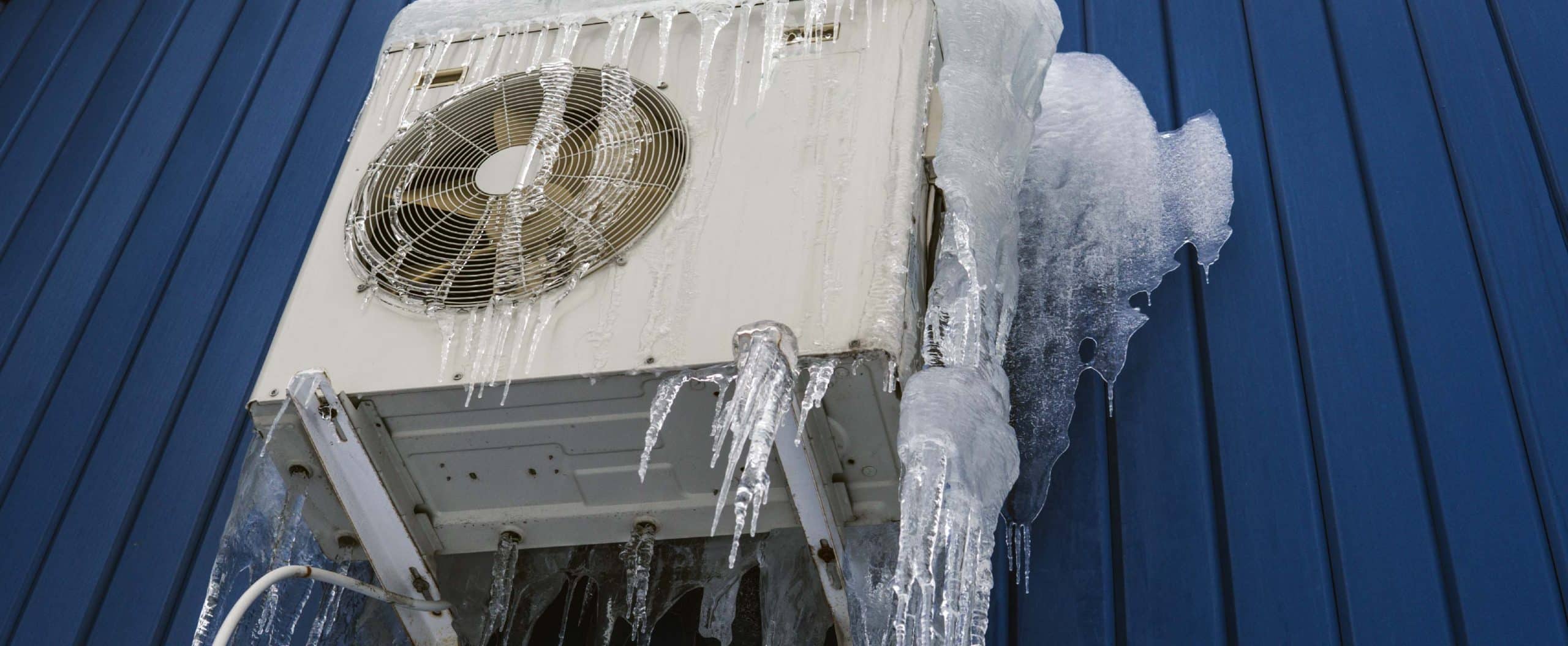

- Evaporator and Condenser Coils: These coils are responsible for heat exchange. Dirty coils reduce efficiency and can lead to icing. The technician will inspect the coils for dirt, debris, and corrosion, and clean them as needed. Think of it like a radiator in a car – if it's clogged, it won't cool the engine effectively.

- Blower Motor and Fan: The blower motor circulates air throughout the system. The technician will inspect the motor for proper operation, lubrication, and any signs of wear. A weak or failing blower motor reduces airflow and can cause overheating.

- Ductwork Inspection: Leaky ductwork wastes energy and reduces comfort. The technician will inspect the ductwork for leaks and damage, and recommend sealing or repair as needed. Studies show that leaky ductwork can account for over 20% of energy loss in some homes.

- Electrical Components: This includes checking wiring, connections, capacitors, and relays for proper operation and safety. Loose connections or failing capacitors can cause system malfunctions and even pose a fire hazard.

- Filter Assessment: A dirty air filter restricts airflow, reduces efficiency, and can damage the equipment. The technician will inspect the filter and recommend replacement as needed. Replacing a dirty filter is one of the easiest and most cost-effective ways to maintain your HVAC system.

- Thermostat Calibration: An improperly calibrated thermostat can lead to inaccurate temperature readings and inefficient operation. The technician will calibrate the thermostat to ensure accurate temperature control.

- Drainage System: Condensation from the evaporator coil needs to drain properly. A clogged drain line can cause water damage and mold growth. The technician will inspect the drain line for clogs and clear it as needed.

Benefits of Regular "ICE" Evaluations

While the upfront cost of an HVAC inspection may seem like an unnecessary expense, the long-term benefits far outweigh the initial investment.

- Improved Energy Efficiency: A well-maintained system operates more efficiently, saving you money on your energy bills.

- Extended Equipment Lifespan: Regular maintenance prevents minor issues from escalating into major repairs, extending the lifespan of your equipment.

- Enhanced Comfort: A properly functioning system provides consistent and comfortable temperatures throughout your home or building.

- Reduced Repair Costs: Identifying and addressing small problems early can prevent costly repairs down the road.

- Improved Indoor Air Quality: Clean coils and filters improve indoor air quality by removing dust, pollen, and other allergens.

- Prevention of Costly Breakdowns: Regular inspection helps to identify weak points and can prevent unexpected failures during peak usage periods. Imagine the discomfort of a broken AC system during a summer heatwave!

"ICE" Evaluation vs. Routine Maintenance

It's important to distinguish between a comprehensive "ICE" evaluation and routine maintenance. Routine maintenance typically involves tasks such as changing air filters, cleaning coils, and lubricating moving parts. An "ICE" evaluation is a more in-depth assessment of the system's overall condition and efficiency. Think of it as the difference between a regular oil change for your car (routine maintenance) and a full diagnostic check-up by a mechanic ("ICE" evaluation). Ideally, a system should have routine maintenance performed regularly (e.g., annually), with a more thorough "ICE" evaluation performed every few years, or whenever performance issues are suspected.

Cost Considerations

The cost of an "ICE" evaluation can vary depending on the complexity of the system, the location, and the HVAC contractor. However, you can generally expect to pay between $150 and $500 for a comprehensive assessment. Remember to get a detailed breakdown of what the evaluation includes before agreeing to the service. Consider the potential savings on energy bills and repair costs when evaluating the value of an "ICE" evaluation.

Choosing an HVAC Professional

When selecting an HVAC professional to perform an "ICE" evaluation, it's important to choose a reputable and experienced company. Look for a company with:

- Proper Licensing and Insurance: Ensure the company is licensed and insured to protect yourself from liability.

- Experienced Technicians: Look for technicians with certifications and experience in diagnosing and repairing HVAC systems.

- Positive Reviews and References: Check online reviews and ask for references from previous customers.

- Transparent Pricing: Get a clear estimate of the cost of the evaluation before work begins.

Examples of System Performance Issues Revealed by an "ICE" Evaluation

Here are some real-world examples of issues that might be uncovered during an "ICE" evaluation:

* Homeowner A noticed their AC unit was running constantly but not cooling the house effectively. An ICE check revealed a significant refrigerant leak, which was causing the system to work harder and consume more energy. Repairing the leak and recharging the system restored its cooling capacity and lowered energy bills. * Facility Manager B observed unusually high energy bills in a commercial building. An ICE exam of the rooftop HVAC units identified several units with dirty condenser coils and restricted airflow. Cleaning the coils and replacing air filters significantly improved the efficiency of the systems and reduced energy consumption. * HVAC Technician C was called to a house with a malfunctioning furnace. An ICE assessment showed a cracked heat exchanger. The homeowner was unaware of this dangerous condition, which posed a carbon monoxide risk. The heat exchanger was replaced, ensuring the safety of the home.Conclusion

While not a formal certification, understanding the concept of an "ICE" (Internal Condition and Efficiency) evaluation is crucial for homeowners, HVAC technicians, and facility managers alike. It represents a proactive approach to HVAC maintenance, focusing on preventing problems and optimizing performance. By investing in regular "ICE" checks, you can ensure your HVAC system operates efficiently, reliably, and safely for years to come, saving money and improving comfort.

By understanding the components of an "ICE" evaluation and its benefits, homeowners can engage in informed discussions with HVAC professionals, ensuring they receive the best possible service. Technicians can use the ICE principles as a framework for comprehensive system diagnostics. Facility managers can incorporate "ICE" evaluations into their preventative maintenance programs to maintain efficient and reliable operation of HVAC systems in large buildings. Remember to always prioritize safety and consult with qualified professionals when dealing with HVAC systems.