What Is Type K Copper Pipe Used For

Understanding Type K Copper Pipe: A Guide for Energy-Efficient HVAC Systems

Copper pipes are a staple in plumbing and HVAC systems, known for their durability and reliability. Among the different types, Type K copper pipe stands out for its robust construction and specific applications. This article dives into what Type K copper pipe is used for, highlighting its benefits, applications in energy-efficient systems, and how it can contribute to lower energy costs and improved ROI for homeowners and businesses alike.

What is Type K Copper Pipe?

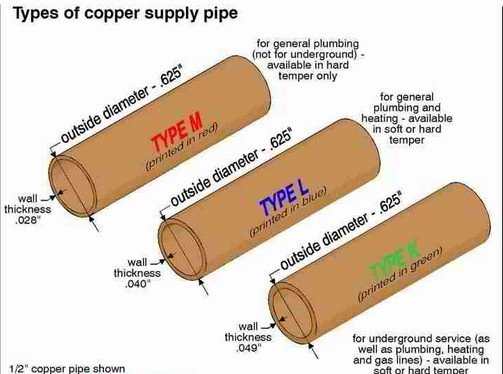

Type K copper pipe is characterized by its thickest wall compared to Type L and Type M copper pipes. This extra thickness translates to higher pressure ratings and enhanced resistance to corrosion. It’s manufactured to meet ASTM B88 standards, ensuring consistent quality and performance. The most common identifiers of Type K copper include its green markings and availability in both rigid and flexible forms.

Primary Applications of Type K Copper Pipe

Due to its strength and durability, Type K copper pipe is often specified in demanding applications. Here's a breakdown:

- Underground Water Service: Type K's corrosion resistance makes it ideal for underground water mains, where it can withstand soil conditions and potential external damage.

- Fire Protection Systems: Its high pressure rating makes it a suitable choice for fire sprinkler systems, where reliability is paramount.

- HVAC Systems: While not as common as Type L in residential HVAC, Type K finds its place in larger commercial and industrial HVAC systems, particularly for refrigerant lines and high-pressure applications.

- Oil and Gas Pipelines: In certain instances, Type K is utilized in low-pressure oil and gas distribution lines due to its ability to resist corrosion from these substances.

- Medical Gas Systems: Hospitals and medical facilities often use Type K for oxygen and other medical gas lines, ensuring purity and safety.

Benefits of Using Type K Copper Pipe in Energy-Efficient Systems

While the initial cost of Type K copper pipe is higher than other types, the long-term benefits can outweigh the upfront investment, especially in energy-efficient systems:

- Longevity and Reduced Maintenance: The superior durability of Type K translates to a longer lifespan, reducing the need for frequent repairs and replacements. This lowers maintenance costs and minimizes disruptions to operations, directly contributing to ROI.

- Corrosion Resistance: Type K's inherent resistance to corrosion is crucial for systems exposed to harsh environments, such as underground installations or coastal areas. This prevents leaks and ensures consistent performance, optimizing energy transfer in HVAC systems.

- High Pressure Rating: In high-pressure HVAC systems, Type K provides a safe and reliable option, minimizing the risk of leaks and failures. This is especially important in large commercial buildings or industrial facilities where system downtime can be costly.

- Improved Energy Efficiency (Indirectly): By minimizing leaks and ensuring system integrity, Type K contributes to improved energy efficiency. A properly sealed system ensures that the HVAC equipment operates at its designed efficiency, preventing energy waste and lowering utility bills.

Type K Copper Pipe in HVAC Systems: Specific Use Cases

Although Type L is more prevalent in typical residential HVAC installations, Type K offers distinct advantages in specific scenarios:

- Large Commercial HVAC Systems: For large chillers and cooling towers, Type K is often preferred for refrigerant lines and condenser water lines due to its high pressure rating and durability.

- Geothermal HVAC Systems: In geothermal systems, where pipes are buried underground, Type K's corrosion resistance makes it a suitable option for ground loop piping.

- District Heating and Cooling: These systems often involve high-pressure and high-temperature fluids. Type K can handle these conditions effectively, ensuring reliable heat transfer.

Smart HVAC Integration and Copper Piping

The integration of smart thermostats and sensors is transforming HVAC systems, making them more energy-efficient and responsive to real-time conditions. While the type of copper pipe used doesn't directly interface with smart technology, its reliability is crucial for ensuring the system operates optimally. Consider these aspects:

- Consistent Performance: Reliable copper piping, like Type K, ensures the HVAC system performs as expected, allowing smart thermostats and sensors to accurately control temperature and airflow.

- Leak Prevention: Leaks in the piping system can undermine the effectiveness of smart controls, leading to inaccurate readings and inefficient operation. Type K's durability minimizes the risk of leaks, preserving the benefits of smart HVAC technology.

- Remote Monitoring: Smart HVAC systems often include remote monitoring capabilities, allowing homeowners or building managers to detect problems early. Using durable piping like Type K reduces the likelihood of issues arising in the first place, improving system reliability.

ROI and Energy Savings: Quantifying the Benefits

Calculating the ROI of using Type K copper pipe involves considering several factors:

- Initial Cost: Type K is more expensive than other types of copper pipe.

- Installation Costs: Installation costs may be slightly higher due to the thicker walls, requiring more time and effort for cutting and joining.

- Maintenance Costs: Type K's durability reduces maintenance costs over the lifespan of the system.

- Energy Savings: By preventing leaks and ensuring system integrity, Type K contributes to energy savings, reducing utility bills.

- Lifespan: Type K's longer lifespan translates to fewer replacements, saving on material and labor costs over the long term.

To quantify energy savings, consider the following:

According to the Energy Star program, a properly maintained HVAC system can reduce energy consumption by up to 20%. Using durable piping like Type K helps ensure the system operates at peak efficiency, maximizing these potential savings. For example, a commercial building with an annual HVAC energy bill of $10,000 could save $2,000 per year with a well-maintained system.

While it is harder to quantify savings directly attributable to the type of pipe, consider the potential cost of a leak. A refrigerant leak in a large commercial system could cost thousands of dollars to repair, including refrigerant replacement and system downtime. Type K minimizes this risk.

Rebates and Incentives for Energy-Efficient HVAC Systems

Many utility companies and government agencies offer rebates and incentives for installing energy-efficient HVAC systems. These incentives can help offset the initial cost of using Type K copper pipe. Homeowners and businesses should research available programs in their area. The Database of State Incentives for Renewables & Efficiency (DSIRE) is a great resource for finding rebates and incentives.

Comparing Type K to Other Copper Pipe Types (L and M)

Here's a quick comparison to understand when to choose Type K:

- Type L: Has a medium wall thickness, making it suitable for most residential plumbing and HVAC applications. It offers a good balance of strength and cost.

- Type M: Has the thinnest wall, making it the least expensive option. It is typically used for low-pressure plumbing applications and is not recommended for high-pressure HVAC systems.

The choice between Type K, L, and M depends on the specific application, pressure requirements, and budget. For high-pressure systems or installations in harsh environments, Type K is the preferred choice. Type L is suitable for most residential applications, while Type M is best suited for low-pressure plumbing.

Installation Best Practices for Type K Copper Pipe

Proper installation is crucial for maximizing the benefits of Type K copper pipe:

- Proper Sizing: Ensure the pipe is sized correctly for the application to minimize pressure drops and ensure adequate flow.

- Professional Installation: Hire a qualified HVAC contractor with experience working with copper piping.

- Proper Joining Techniques: Use appropriate soldering or brazing techniques to create strong and leak-proof joints.

- Support and Protection: Properly support the pipe to prevent sagging and strain. Protect it from physical damage, especially in underground installations.

- Insulation: Insulate the pipe to minimize heat loss or gain, improving energy efficiency.

Conclusion: Is Type K Copper Pipe Right for Your Project?

Type K copper pipe offers superior durability, corrosion resistance, and pressure ratings, making it a valuable choice for specific applications, particularly in large commercial HVAC systems, geothermal systems, and underground installations. While the initial cost is higher, the long-term benefits of reduced maintenance, improved energy efficiency, and increased lifespan can outweigh the upfront investment.

For homeowners and businesses seeking to upgrade to energy-efficient systems, carefully consider the specific requirements of your project. Consult with a qualified HVAC contractor to determine if Type K copper pipe is the right choice for your needs. By making informed decisions and investing in durable materials, you can achieve significant energy savings and improve the ROI of your HVAC system.