What Type Of Pipe Is Used For Natural Gas Lines

Understanding the piping systems used for natural gas is critical for homeowners, HVAC technicians, and facility managers alike. The safe and efficient delivery of natural gas depends heavily on the appropriate choice of piping materials. Selecting the wrong type of pipe can lead to leaks, corrosion, and even hazardous situations. This article provides a comprehensive overview of the types of pipe approved for natural gas lines, along with considerations for installation, maintenance, and relevant safety codes.

Approved Piping Materials for Natural Gas Lines

Several types of piping are commonly used for natural gas distribution, each with its own advantages and disadvantages. The most common options include:

Black Iron Pipe

Black iron pipe is a traditional and widely used material for both indoor and outdoor natural gas lines. It's known for its durability and resistance to mechanical damage. The "black" refers to a protective coating applied during manufacturing that helps prevent rust and corrosion, though this coating is not foolproof, especially in damp environments.

Advantages of Black Iron Pipe:

- High Strength: Can withstand high pressures and physical impacts.

- Heat Resistance: Suitable for use near furnaces and water heaters.

- Familiarity: Most HVAC technicians are well-versed in its installation and repair.

Disadvantages of Black Iron Pipe:

- Susceptibility to Corrosion: Can rust, especially in humid environments, requiring periodic inspection and maintenance.

- Labor-Intensive Installation: Requires cutting, threading, and joining with pipe dope, which can be time-consuming.

- Weight: Relatively heavy, making handling and installation more difficult.

Black iron pipes are typically joined using threaded connections, which require the application of a pipe joint compound (pipe dope) to ensure a gas-tight seal. Proper threading and sealing are critical to prevent leaks. Consider that poorly sealed joints are a common cause of gas leaks and can lead to significant safety hazards and increased energy bills.

Galvanized Steel Pipe

Galvanized steel pipe is steel pipe that has been coated with a layer of zinc to protect it from corrosion. While it offers some corrosion resistance, it is generally not recommended for natural gas lines due to the potential for the zinc coating to react with the natural gas, leading to the formation of zinc oxides that can clog the gas lines and appliances. This is a critical consideration for both residential and commercial applications.

Why Galvanized Steel Should Be Avoided:

- Zinc Oxide Formation: Reaction between zinc and natural gas can cause clogging.

- Reduced Gas Flow: Clogs can reduce the efficiency of gas appliances.

- Potential Damage to Appliances: Reduced gas flow can damage appliances and lead to malfunctions.

Although galvanized steel may appear similar to black iron pipe, it is crucial to distinguish between the two and avoid using galvanized steel for natural gas applications.

Copper Tubing (Type L or Type K)

Copper tubing, specifically Type L or Type K, can be used for natural gas lines in some jurisdictions, but it's essential to check local codes. Type L copper is commonly used for plumbing and can be suitable for natural gas if permitted. Type K is thicker and more durable, offering greater resistance to pressure and corrosion.

Advantages of Copper Tubing:

- Corrosion Resistance: Highly resistant to corrosion, especially compared to black iron.

- Flexibility: Can be bent to navigate around obstacles, reducing the need for fittings.

- Ease of Installation: Can be joined using soldering or brazing, which can be faster than threading black iron.

Disadvantages of Copper Tubing:

- Cost: Generally more expensive than black iron pipe.

- Potential for Theft: Copper is a valuable metal, making it susceptible to theft.

- Reaction with Certain Gases: In some rare cases, specific contaminants in natural gas can react with copper.

When using copper tubing, it's crucial to ensure that it's properly supported and protected from physical damage. Proper grounding is also essential to prevent galvanic corrosion where copper connects to other metals. Employing a licensed and experienced technician is particularly important when working with copper in gas line applications.

Polyethylene (PE) Pipe

Polyethylene (PE) pipe is a flexible plastic pipe commonly used for underground natural gas distribution lines. It is typically yellow or orange in color to indicate its use for gas. PE pipe is connected using heat fusion, creating a strong and leak-free joint. This method involves heating the ends of the pipes and fusing them together.

Advantages of Polyethylene (PE) Pipe:

- Corrosion Resistance: Highly resistant to corrosion, making it ideal for underground use.

- Flexibility: Can be easily bent and routed around obstacles.

- Cost-Effective: Generally less expensive than metal piping for underground applications.

Disadvantages of Polyethylene (PE) Pipe:

- Not Suitable for Indoor Use: Typically not approved for indoor gas lines.

- Susceptibility to Damage: Can be damaged by sharp objects or improper handling during installation.

- Specialized Installation: Requires specialized equipment and training for heat fusion joining.

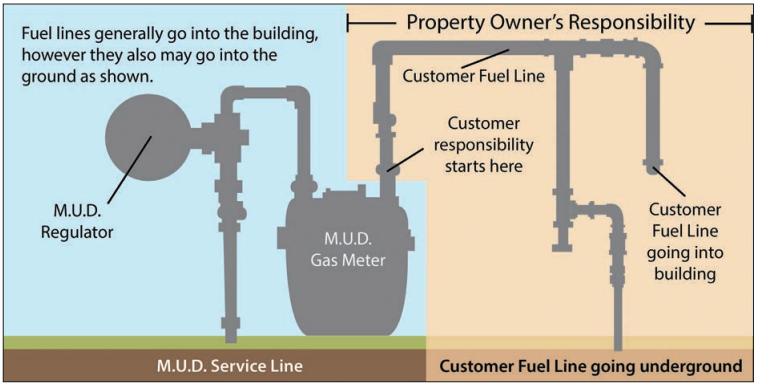

PE pipe is typically used for the main gas line running from the street to the building. From there, it usually transitions to black iron or another approved material for indoor distribution.

Corrugated Stainless Steel Tubing (CSST)

Corrugated Stainless Steel Tubing (CSST) is a flexible stainless steel tubing that is often used for indoor natural gas lines. It is coated with a yellow or black polyethylene jacket for protection. CSST offers several advantages, including its flexibility and ease of installation, but it is crucial to ensure that it is properly bonded to the electrical grounding system to protect against lightning strikes.

Advantages of Corrugated Stainless Steel Tubing (CSST):

- Flexibility: Can be easily bent and routed around obstacles, reducing the need for fittings.

- Ease of Installation: Can be installed quickly and easily, reducing labor costs.

- Corrosion Resistance: Stainless steel is highly resistant to corrosion.

Disadvantages of Corrugated Stainless Steel Tubing (CSST):

- Lightning Strike Risk: Can be punctured by lightning strikes if not properly bonded.

- Cost: Generally more expensive than black iron pipe.

- Proper Bonding Required: Proper bonding to the electrical grounding system is essential for safety.

Bonding involves connecting the CSST to the building's grounding system, providing a path for electrical current to flow in the event of a lightning strike. Without proper bonding, a lightning strike can puncture the CSST, leading to a gas leak and potential fire. The manufacturers of CSST products provide detailed instructions on proper bonding techniques. It is also crucial to have a qualified electrician perform the bonding process.

Important Considerations for Installation and Maintenance

Regardless of the type of piping material used, proper installation and maintenance are essential for ensuring the safe and efficient operation of natural gas lines.

- Adherence to Codes: All installations must comply with local and national codes. These codes specify the types of piping materials that are allowed, as well as the requirements for installation, testing, and maintenance.

- Pressure Testing: After installation, gas lines must be pressure-tested to ensure that they are leak-free. This involves pressurizing the lines with air or nitrogen and checking for any leaks using a soap solution.

- Regular Inspections: Regular inspections of gas lines are essential to identify and address any potential problems before they become serious. Look for signs of corrosion, damage, or leaks.

- Professional Installation: It is always recommended to have natural gas lines installed by a licensed and qualified HVAC technician or plumber. They have the knowledge, skills, and experience to ensure that the installation is done safely and correctly.

- Carbon Monoxide Detectors: Install carbon monoxide (CO) detectors near all sleeping areas. CO is a colorless, odorless gas that can be deadly.

Cost Considerations

The cost of piping materials and installation can vary depending on several factors, including the type of piping material, the length of the gas line, and the complexity of the installation. Black iron pipe is typically the least expensive option, while copper and CSST are generally more expensive. However, the long-term costs may differ due to factors like corrosion resistance and ease of installation.

For example, while black iron pipe might have a lower initial cost, it may require more maintenance and replacement due to corrosion, especially in humid environments. Copper and CSST, on the other hand, may have a higher initial cost but offer longer lifespan and reduced maintenance costs.

When comparing costs, it's essential to consider the total cost of ownership, including materials, labor, maintenance, and potential replacement costs. Consulting with a qualified HVAC technician can help you determine the most cost-effective solution for your specific needs.

Conclusion

Choosing the right type of pipe for natural gas lines is a crucial decision that affects safety, efficiency, and long-term costs. Black iron pipe, copper tubing, polyethylene (PE) pipe, and corrugated stainless steel tubing (CSST) are all viable options, each with its own set of advantages and disadvantages. Understanding the properties of each material and adhering to local codes and regulations are essential for ensuring a safe and reliable natural gas system. Regular inspections and professional installation by licensed technicians are also critical for maintaining the integrity of the system and preventing potential hazards. Always prioritize safety and consult with qualified professionals when dealing with natural gas systems.