Where Do Carbon Monoxide Leaks Come From

Carbon monoxide (CO) is a silent killer. As an HVAC professional, understanding where CO leaks originate is paramount to protecting your clients and building a successful, responsible career. This article will delve into the common sources of CO leaks, offering insights for students, seasoned technicians, and employers in the HVAC industry.

Common Sources of Carbon Monoxide Leaks: A Technician's Guide

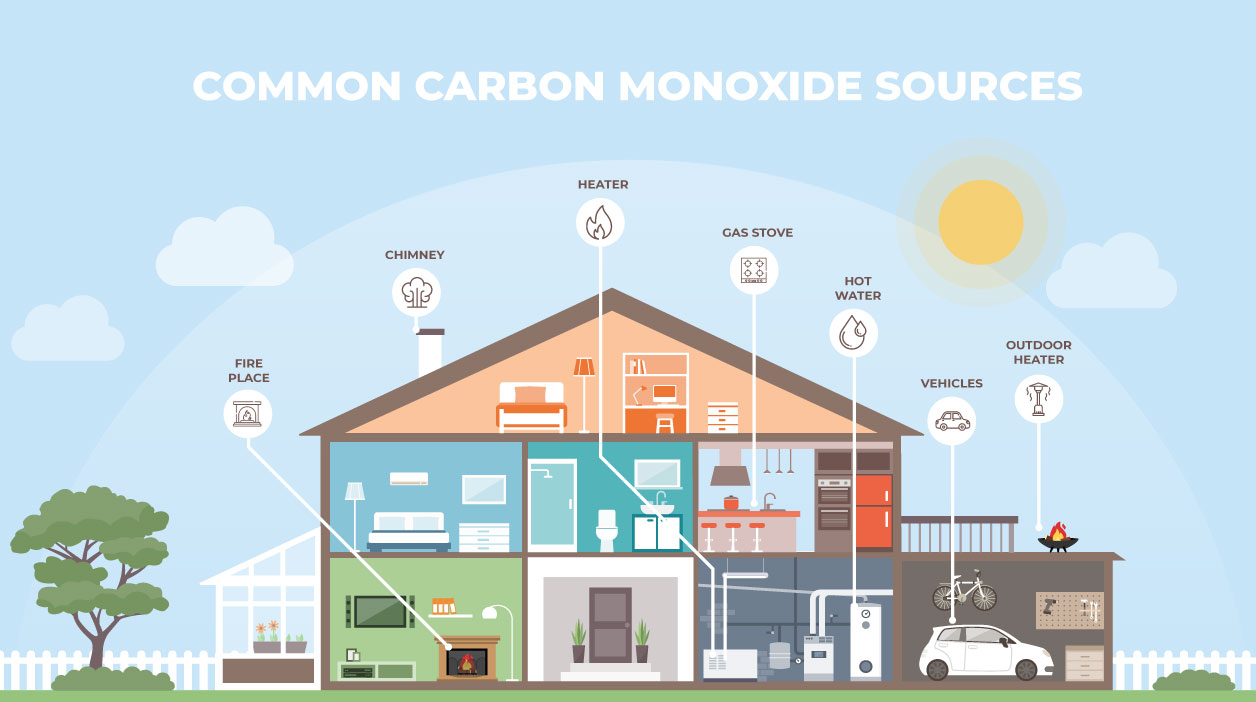

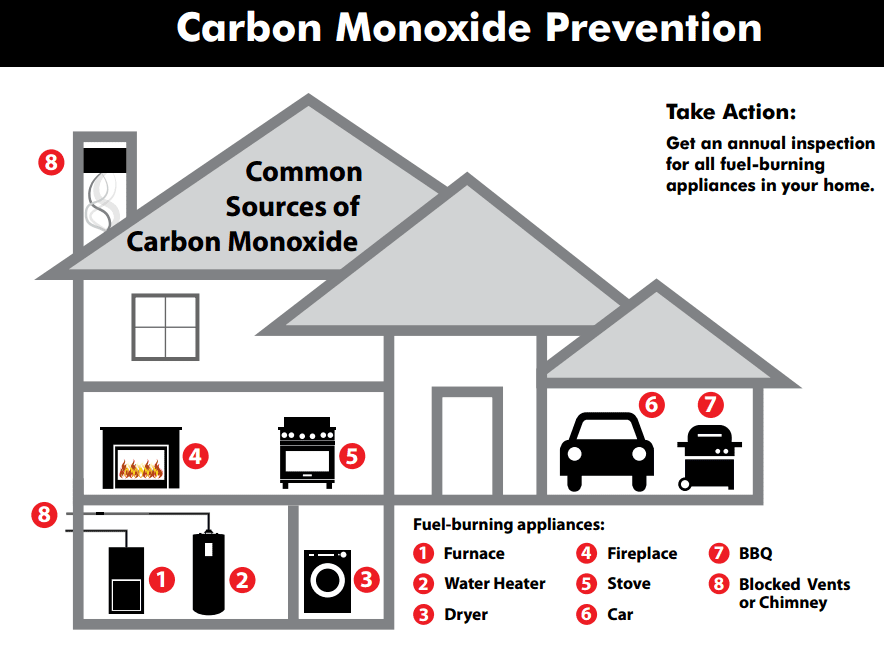

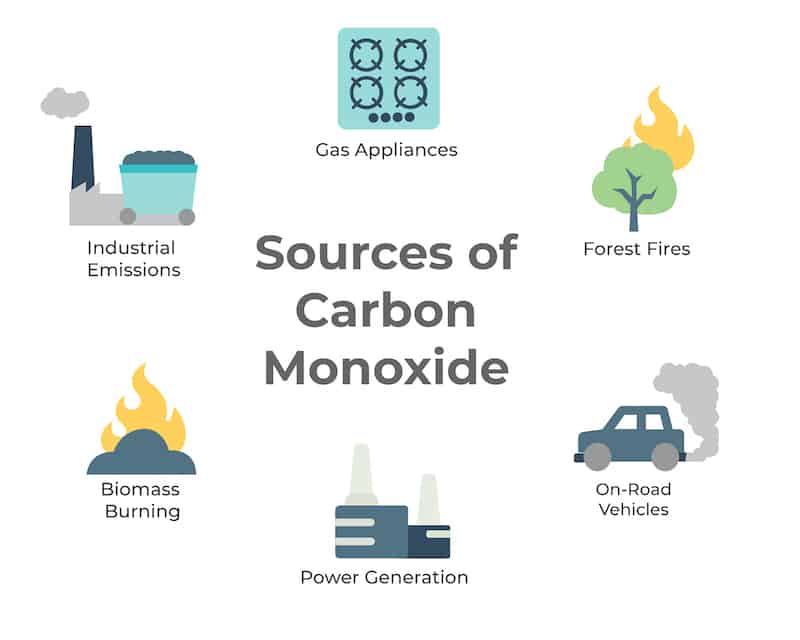

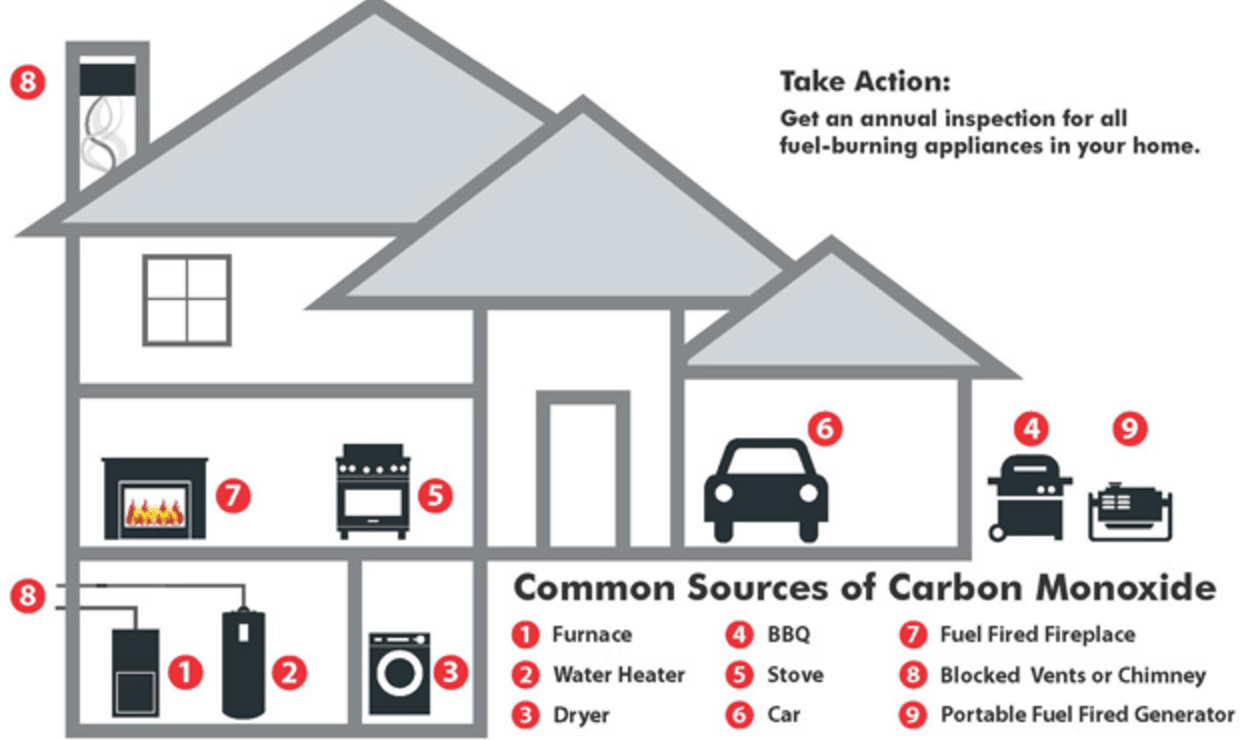

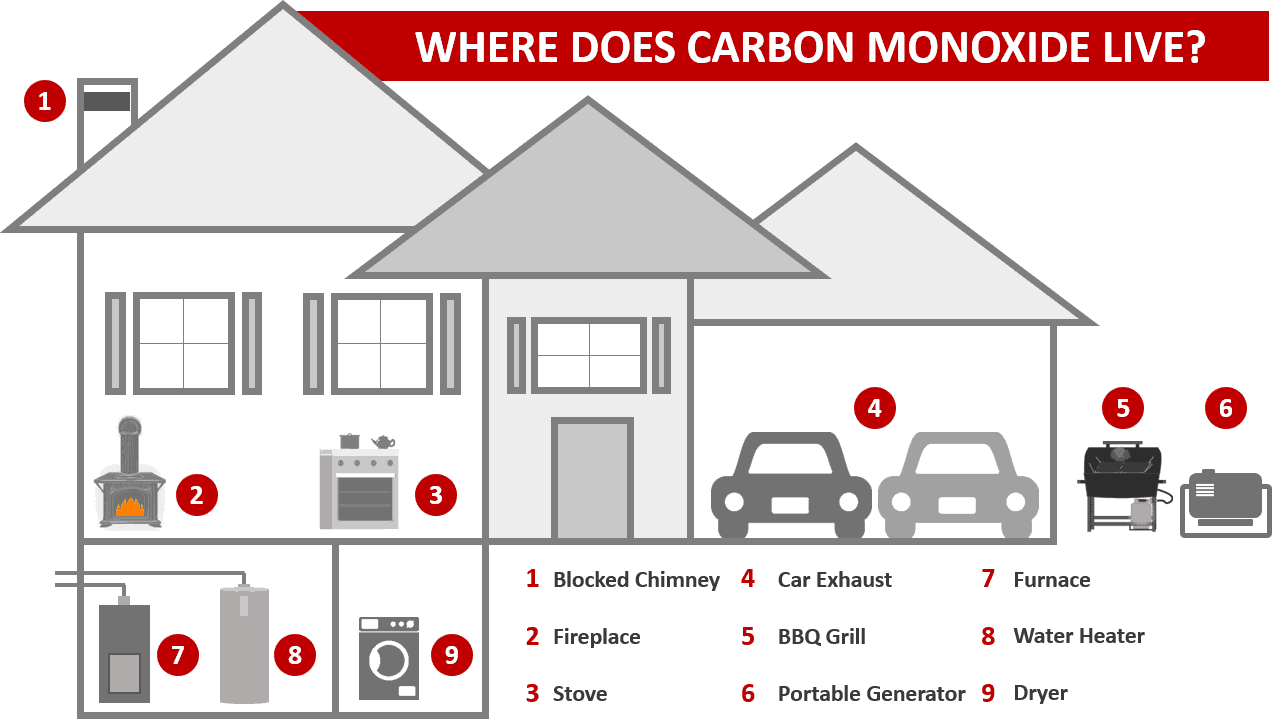

CO is a byproduct of incomplete combustion. This means that whenever fuel is burned without sufficient oxygen, CO is produced. In residential and commercial settings, this typically involves appliances that burn natural gas, propane, oil, wood, or kerosene. Here's a breakdown of the most frequent culprits:

Furnaces: The Primary Suspect

Furnaces, particularly older models, are a leading cause of CO leaks. Cracks in the heat exchanger, a component responsible for separating combustion gases from the air circulated throughout the building, are a major concern. These cracks can develop over time due to thermal stress and corrosion. Regular inspections, including combustion analysis, are crucial for detecting these issues early on. Leaking flue pipes that vent exhaust gases outside of the building can also introduce CO into the occupied space.

Real-world Example: I once responded to a call where a family was experiencing flu-like symptoms. The homeowner insisted it wasn't CO, but a quick combustion analysis of the furnace revealed dangerously high levels. A cracked heat exchanger was the culprit. Had they ignored the symptoms, the outcome could have been tragic.

Water Heaters: Often Overlooked

Like furnaces, gas-fired water heaters rely on combustion. Issues such as blocked flues, improper venting, or burner malfunctions can lead to CO production and subsequent leaks. Sediment buildup in the tank can also reduce efficiency, increasing the risk of incomplete combustion. Regular maintenance, including flushing the tank and inspecting the flue, is essential.

Fireplaces: A Traditional Hazard

Wood-burning fireplaces, while aesthetically pleasing, can be significant sources of CO if not properly maintained. Blocked chimneys, inadequate airflow, and incomplete combustion due to wet or poorly seasoned wood all contribute to the risk. Ensure proper ventilation and advise clients to use only dry, seasoned wood. Chimney inspections and cleaning are critical for safe operation.

Gas Stoves and Ovens: Kitchen Concerns

Although designed for cooking, gas stoves and ovens can produce CO, especially if burners are not properly adjusted or if ventilation is inadequate. Never use a gas oven to heat a home; this is a dangerous practice that can quickly lead to CO poisoning. Ensure proper ventilation by using the range hood when cooking.

Portable Generators: An Outdoor Threat

Portable generators are particularly dangerous when used indoors or in enclosed spaces. Generators produce significant amounts of CO, and even a short period of operation in an enclosed area can lead to fatal levels. Always operate generators outdoors, away from windows, doors, and vents.

Vehicles: Garage Dangers

Running a car in a garage, even with the door open, can quickly lead to dangerous CO buildup. Exhaust fumes contain high concentrations of CO, and even brief exposure can be harmful. Never run a vehicle in an enclosed garage.

Other Potential Sources

Other potential sources of CO leaks include kerosene heaters, charcoal grills (never use indoors!), and even some power tools that use combustion engines. The key is to understand the principle of incomplete combustion and to be aware of any appliance that burns fuel.

HVAC Career Paths and CO Safety

Understanding CO safety is not just a technical skill; it's a critical aspect of ethical HVAC practice. The ability to diagnose and address CO issues directly impacts the health and safety of your clients, making you a valuable asset to any HVAC company.

Entry-Level Technicians and Apprenticeships

For those just starting out, a strong foundation in HVAC principles is essential. Apprenticeships provide invaluable hands-on experience, allowing you to learn from experienced technicians. Focusing on combustion analysis, equipment maintenance, and CO detection techniques during your training will set you up for success. Entry-level HVAC technician positions typically earn between $35,000 and $50,000 annually, depending on location and experience. The job outlook for HVAC technicians is projected to grow 6 percent from 2022 to 2032, about as fast as the average for all occupations, according to the Bureau of Labor Statistics.

Experienced Technicians and Certifications

Experienced technicians can enhance their skills and career prospects by obtaining relevant certifications. The North American Technician Excellence (NATE) certification is highly regarded in the industry and demonstrates a technician's competence. The Environmental Protection Agency (EPA) Section 608 certification is required for technicians who handle refrigerants. These certifications not only validate your skills but also increase your earning potential. Senior HVAC technicians and specialists can earn upwards of $70,000 or more annually.

For those interested in specializing, consider focusing on combustion analysis and indoor air quality (IAQ). Becoming a certified IAQ professional can open doors to higher-paying positions and specialized work.

Employers and CO Safety Protocols

HVAC employers have a responsibility to ensure the safety of their employees and clients. This includes providing adequate training on CO detection and mitigation, equipping technicians with the necessary tools (such as CO detectors and combustion analyzers), and establishing clear safety protocols. Investing in employee training and safety equipment not only protects your workforce but also enhances your company's reputation and reduces liability.

Hiring Tip: When hiring HVAC technicians, prioritize candidates with strong knowledge of CO safety and relevant certifications. Ask specific questions about their experience with combustion analysis and their understanding of CO sources. Look for technicians who demonstrate a commitment to safety and a willingness to learn.

The Role of Technology in CO Detection

Technological advancements have significantly improved CO detection and prevention. Modern CO detectors are more sensitive and reliable than older models. Some detectors can even be integrated with smart home systems, providing remote monitoring and alerts.

Combustion analyzers have also become more sophisticated, providing detailed information about combustion efficiency and CO levels. These tools enable technicians to quickly and accurately diagnose combustion-related problems.

Staying up-to-date on the latest technological advancements in CO detection is crucial for HVAC professionals. Investing in new tools and training can significantly improve your ability to identify and address CO issues.

Legal and Ethical Considerations

HVAC professionals have a legal and ethical obligation to protect their clients from CO poisoning. Failure to properly diagnose and address CO issues can have serious consequences, including liability for damages and even criminal charges.

Always follow industry best practices and local codes when installing and maintaining HVAC equipment. Educate your clients about the dangers of CO and the importance of regular maintenance. Document all inspections and repairs to demonstrate your due diligence.

Conclusion: Prioritizing Safety and Expertise

Carbon monoxide leaks pose a serious threat, but with the right knowledge, skills, and tools, HVAC professionals can play a vital role in preventing CO poisoning. Whether you're a student, a seasoned technician, or an employer, prioritizing CO safety is essential for building a successful and responsible career in the HVAC industry. By staying informed, pursuing certifications, and embracing new technologies, you can make a real difference in the lives of your clients and the safety of your community.

Remember to always emphasize preventative maintenance. Scheduling regular check-ups for furnaces, water heaters, and other fuel-burning appliances can help identify potential problems before they become dangerous. Proactive maintenance is the best defense against carbon monoxide leaks.