Why Do I Need A Carbon Monoxide Detector

Carbon monoxide (CO) is an invisible, odorless, and deadly gas. Knowing why you need a carbon monoxide detector is crucial, not just for personal safety, but also for professionals in the HVAC industry. This article provides a comprehensive overview, explaining the risks of CO poisoning, the role of HVAC systems, legal requirements, detector maintenance, and career opportunities related to CO detection and safety.

The Silent Killer: Understanding Carbon Monoxide

Carbon monoxide is produced by the incomplete combustion of fuels such as natural gas, propane, oil, wood, and gasoline. Common sources include furnaces, water heaters, gas stoves, fireplaces, and vehicles. Because CO is odorless and colorless, it’s virtually undetectable without specialized equipment. Exposure can cause flu-like symptoms, dizziness, confusion, loss of consciousness, and even death. According to the CDC, over 400 Americans die annually from unintentional CO poisoning, and thousands more require medical attention.

Consider this scenario: a family experiences headaches and nausea for several days. They attribute it to a virus, unaware that a cracked heat exchanger in their furnace is leaking CO into their home. Without a detector, the situation could quickly become fatal.

HVAC Systems: A Primary Source of CO

HVAC systems, particularly furnaces and boilers, are often the primary source of CO leaks in homes and buildings. Cracks in heat exchangers, blocked flues, and improper venting can all lead to CO buildup. Regular maintenance and inspections are essential to prevent these issues. As an HVAC professional, you play a vital role in ensuring the safe operation of these systems.

For example, a technician performing an annual furnace tune-up might identify a hairline crack in the heat exchanger. By recommending replacement, they prevent a potentially deadly CO leak, showcasing the critical importance of their work.

Legal Requirements and Building Codes

Many states and municipalities have laws requiring CO detectors in residential buildings, particularly those with fuel-burning appliances or attached garages. These regulations are designed to protect occupants from the dangers of CO poisoning. Building codes also often specify the placement and type of detectors required.

Staying up-to-date on local and national codes is paramount for HVAC professionals. Ignorance of these regulations can lead to liability issues and, more importantly, endanger lives. Consulting resources like the International Mechanical Code (IMC) and the National Fuel Gas Code (NFGC) is highly recommended.

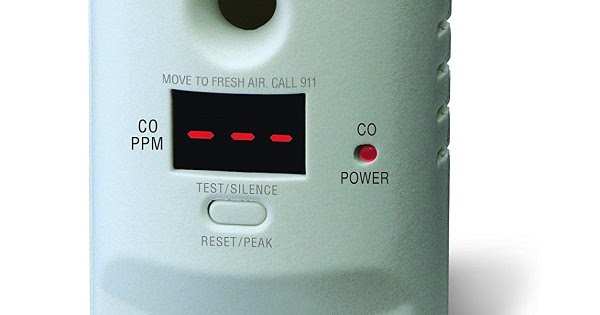

Types of Carbon Monoxide Detectors

There are several types of CO detectors available, each with its own advantages and disadvantages:

- Electrochemical sensors: These are the most common type, offering good accuracy and longevity.

- Biometric sensors: These change color in the presence of CO.

- Metal oxide semiconductor sensors: These detect CO based on changes in electrical conductivity.

Detectors can be battery-powered, hardwired, or plug-in. Combination smoke and CO detectors are also available. When selecting a detector, look for models certified by a reputable testing organization like Underwriters Laboratories (UL).

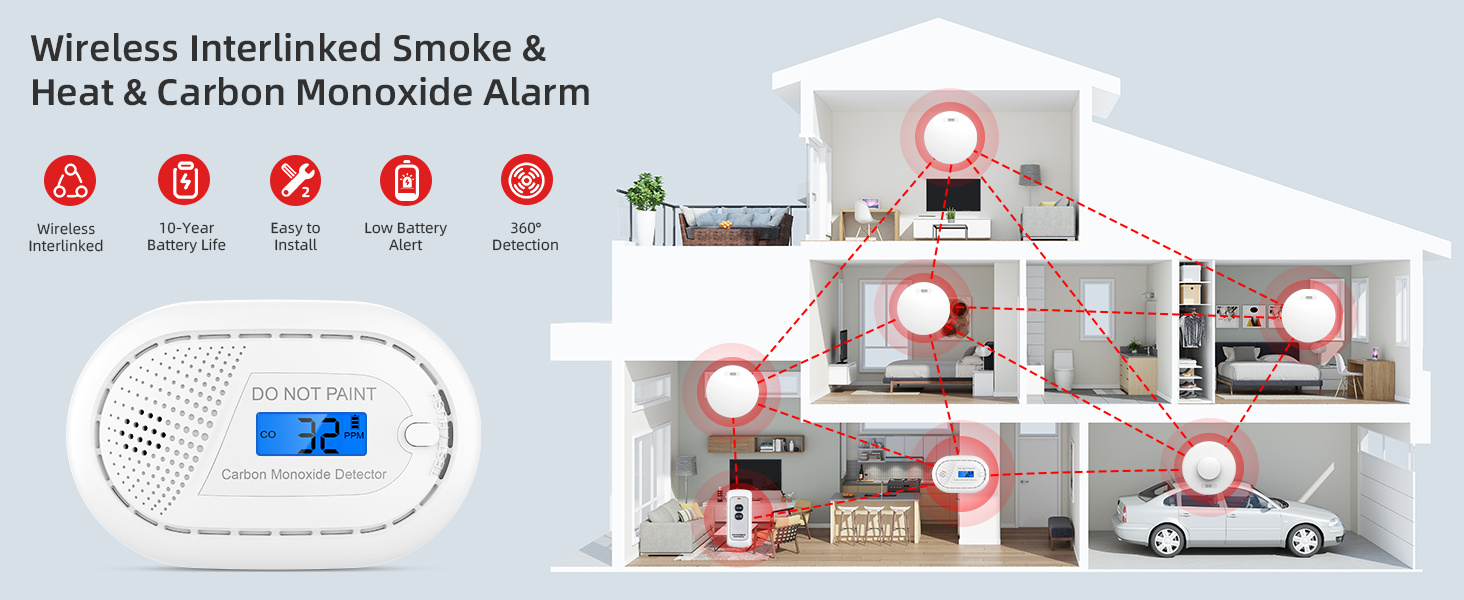

Proper Placement and Maintenance

Proper placement is crucial for CO detectors to function effectively. Follow these guidelines:

- Install detectors on each level of the home, including the basement.

- Place detectors near sleeping areas.

- Avoid placing detectors near fuel-burning appliances, as brief, harmless CO emissions can trigger false alarms.

- Do not place detectors in dusty or humid areas.

Regular maintenance is also essential. Test detectors monthly by pressing the test button. Replace batteries annually, unless the detector has a sealed 10-year battery. Replace detectors every 5-10 years, as the sensors degrade over time.

The HVAC Technician's Role in CO Safety

HVAC technicians play a vital role in preventing CO poisoning. This includes:

- Performing thorough inspections: Check for cracks in heat exchangers, proper venting, and other potential CO hazards.

- Educating homeowners: Explain the risks of CO poisoning and the importance of detectors.

- Installing CO detectors: Offer CO detector installation as part of your service.

- Responding to CO alarms: Know how to properly investigate and address CO alarms.

By taking these steps, HVAC technicians can significantly reduce the risk of CO poisoning and protect their customers.

Career Opportunities in HVAC and CO Safety

The HVAC industry offers a wide range of career opportunities, many of which involve CO safety. These include:

- HVAC Technician: Installs, maintains, and repairs HVAC systems, including performing CO safety checks. The Bureau of Labor Statistics projects a growth rate of 6% for HVAC mechanics and installers from 2022 to 2032. The median annual wage for HVAC mechanics and installers was $51,390 in May 2022.

- HVAC Installer: Focuses on the installation of new HVAC systems, ensuring proper venting and CO safety.

- HVAC Service Technician: Provides maintenance and repair services, including CO detector testing and CO leak detection.

- Building Inspector: Inspects buildings to ensure compliance with safety codes, including CO detector requirements.

- Home Inspector: Conducts home inspections for buyers and sellers, identifying potential CO hazards.

Advancement opportunities exist for experienced technicians, such as becoming a supervisor, project manager, or starting their own HVAC business.

Certifications and Training

Several certifications can enhance your skills and credentials in the HVAC industry, including those related to CO safety:

- NATE (North American Technician Excellence): Offers certification exams for various HVAC specialties, demonstrating competency and professionalism. NATE certification is often preferred by employers.

- EPA 608 Certification: Required for technicians who handle refrigerants, and demonstrates understanding of environmental regulations.

- Carbon Monoxide Safety Certification: Some organizations offer specialized training and certification in CO safety, covering detection, prevention, and response.

Continuous learning is essential in the HVAC industry. Staying up-to-date on new technologies, regulations, and best practices will enhance your career prospects and ensure you provide the best possible service to your customers.

Salary Expectations

Salaries in the HVAC industry vary depending on experience, location, and certifications. According to the Bureau of Labor Statistics, the median annual wage for HVAC mechanics and installers was $51,390 in May 2022. However, experienced technicians with specialized skills and certifications can earn significantly more. For example, a NATE-certified technician with expertise in CO safety could command a higher salary than a less experienced technician.

Starting salaries for entry-level HVAC technicians typically range from $35,000 to $45,000 per year. With experience and additional training, salaries can increase to $60,000 or more. Supervisors and managers in the HVAC industry can earn $75,000 or more per year.

Real-World Examples

Consider the career path of Sarah, an HVAC apprentice. She started by assisting experienced technicians with routine maintenance and repairs. Over time, she gained expertise in CO safety and earned her NATE certification. Today, she is a lead technician, responsible for inspecting HVAC systems for CO leaks and educating homeowners about the importance of CO detectors. Her dedication to safety has made her a valuable asset to her company and a trusted resource for her customers.

Another example is John, who started his own HVAC business after years of experience as a technician. He recognized the growing demand for CO safety services and made it a core part of his business. He invested in specialized equipment for detecting CO leaks and trained his employees to provide comprehensive CO safety inspections. His business has thrived by providing reliable and trustworthy service to his community.

Conclusion

Understanding why you need a carbon monoxide detector is not just a matter of personal safety; it's also a critical aspect of the HVAC industry. As an HVAC professional, you have a responsibility to protect your customers from the dangers of CO poisoning. By staying informed, providing thorough inspections, and educating homeowners, you can make a significant difference in the lives of others. Furthermore, focusing on this specialization can lead to fulfilling and financially rewarding career opportunities. Invest in your training, earn relevant certifications, and prioritize CO safety in your work.