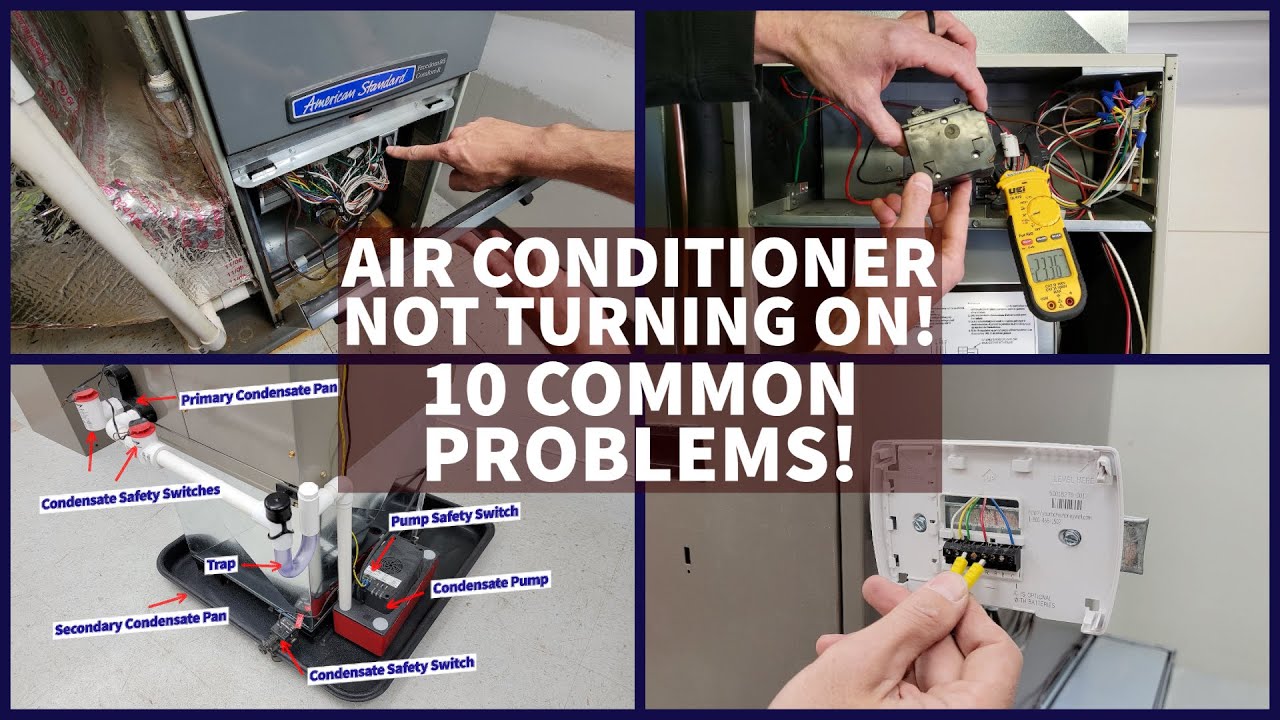

Why Is My Ac Unit Outside Not Turning On

Troubleshooting a Silent Outdoor AC Unit: A Comprehensive Guide

A sweltering summer day is no time for your outdoor AC unit to decide to take a break. When the compressor refuses to kick on, it signals a problem that demands immediate attention. This article provides a structured approach to diagnosing and resolving the issue, geared towards HVAC students, seasoned technicians, and employers looking to understand the intricacies of HVAC systems.

Understanding the Importance of Proper Diagnosis

Before diving into potential causes, it's crucial to emphasize the importance of a systematic diagnosis. Jumping to conclusions can lead to unnecessary repairs and increased costs. A methodical approach, leveraging tools like multimeters and clamp meters, is essential for accurately identifying the root cause.

Common Reasons Your Outdoor AC Unit Isn't Turning On

1. Power Issues

This is often the simplest, yet most overlooked, area to check. Verify the following:

- Breaker Trip: The circuit breaker dedicated to your AC unit may have tripped. Reset it and see if the unit starts. If it trips again immediately, there's likely a more serious electrical issue.

- Disconnect Switch: Ensure the outdoor disconnect switch, usually located near the unit, is in the "on" position. Sometimes, accidental bumping or maintenance can switch it off.

- Voltage Supply: Use a multimeter to check the voltage at the disconnect switch and at the unit itself. Insufficient voltage can prevent the compressor from starting.

2. Thermostat Problems

The thermostat acts as the brain of your HVAC system. If it's malfunctioning, it won't signal the outdoor unit to turn on.

- Thermostat Settings: Confirm the thermostat is set to "cool" and the temperature is lower than the current room temperature.

- Battery Issues: If you have a digital thermostat, check the batteries. Low batteries can cause erratic behavior.

- Wiring Problems: Inspect the wiring connections at the thermostat. Loose or corroded wires can disrupt the signal.

3. Capacitor Failure

Capacitors are essential components that provide the electrical jolt needed to start the compressor and fan motor. A failed capacitor is a common cause of AC unit failure.

- Testing Capacitors: Use a capacitor tester to check the capacitance value. A reading outside the specified range indicates a faulty capacitor.

- Visual Inspection: Look for signs of bulging, leaking, or physical damage to the capacitor.

- Safety Precautions: Always discharge the capacitor before handling it to avoid electric shock.

4. Contactor Issues

The contactor is an electrical switch that controls the flow of power to the compressor and fan motor. It can become corroded or damaged over time.

- Visual Inspection: Check the contactor for signs of corrosion, pitting, or burned contacts.

- Testing the Contactor: Use a multimeter to test the continuity of the contacts. A faulty contactor will not allow current to flow.

5. Compressor Problems

The compressor is the heart of the AC unit. If it fails, the entire unit will be inoperable. Compressor issues are often more complex and may require specialized tools and knowledge.

- Overheating: The compressor may be overheating due to refrigerant issues or mechanical problems.

- Locked Rotor: A locked rotor indicates a mechanical failure within the compressor.

- Burned Winding: The motor windings inside the compressor may have burned out.

6. Refrigerant Leaks

Low refrigerant levels can prevent the compressor from starting or cause it to shut down prematurely. Refrigerant leaks are harmful to the environment and must be addressed by a qualified technician. According to the EPA, technicians handling refrigerants must be EPA 608 certified.

- Leak Detection: Use electronic leak detectors or bubble solutions to locate refrigerant leaks.

- Repairing Leaks: Leaks must be repaired before refrigerant is added.

- Proper Refrigerant Handling: Ensure proper refrigerant recovery and disposal practices are followed.

7. Dirty Condenser Coils

Dirty condenser coils reduce the AC unit's ability to dissipate heat, leading to overheating and potential shutdown. Regular cleaning is essential for maintaining optimal performance.

- Visual Inspection: Check the condenser coils for dirt, debris, and obstructions.

- Cleaning Procedures: Use a fin comb and a garden hose to clean the coils gently.

HVAC Industry Outlook and Career Paths

The HVAC industry is experiencing strong growth, driven by increasing demand for energy-efficient systems and a growing emphasis on indoor air quality. The Bureau of Labor Statistics projects a significant increase in employment for HVAC technicians over the next decade.

Career Paths:

- Entry-Level Technician: Typically involves installation, maintenance, and repair of HVAC systems under the supervision of experienced technicians. Average salary ranges from $40,000 to $50,000 per year.

- Service Technician: Focuses on diagnosing and repairing HVAC systems. Requires strong troubleshooting skills and knowledge of electrical and mechanical systems. Average salary ranges from $50,000 to $65,000 per year.

- Installation Technician: Specializes in the installation of new HVAC systems. Requires knowledge of building codes and proper installation techniques. Average salary ranges from $45,000 to $60,000 per year.

- HVAC Systems Designer: Designs and engineers HVAC systems for residential and commercial buildings. Requires a strong understanding of thermodynamics, fluid mechanics, and building codes. Average salary ranges from $65,000 to $85,000 per year or higher.

- HVAC Sales Engineer: Works with clients to design and sell HVAC systems. Requires strong technical knowledge and sales skills. Average salary ranges from $70,000 to $90,000 per year or higher.

The Value of Certifications

Certifications demonstrate a technician's knowledge and skills, enhancing their credibility and marketability. Some key certifications include:

- NATE (North American Technician Excellence): NATE certification is widely recognized and respected in the HVAC industry. It demonstrates a technician's competency in specific areas of HVAC, such as installation, service, and maintenance.

- EPA 608 Certification: Required for technicians who handle refrigerants. It ensures they understand proper refrigerant handling procedures and environmental regulations.

- HVAC Excellence: Offers certifications in various HVAC specialties, demonstrating a technician's expertise in specific areas.

Investing in Training and Education

A solid foundation in HVAC principles is essential for success in this field. Consider the following educational pathways:

- Vocational Schools: Offer hands-on training and technical skills development.

- Apprenticeship Programs: Provide on-the-job training under the guidance of experienced technicians.

- Associate's Degree Programs: Offer a more comprehensive education in HVAC technology.

- Bachelor's Degree Programs: Focus on engineering and design aspects of HVAC systems.

Real-World Example: From Apprentice to Business Owner

Consider the career path of Maria Rodriguez, a successful HVAC business owner in Austin, Texas. Maria started as an apprentice, gaining hands-on experience while working towards her NATE certification. She then worked as a service technician, honing her troubleshooting skills and building a strong reputation for reliability. After several years, Maria decided to start her own business, leveraging her technical expertise and customer service skills. Today, her company employs several technicians and provides HVAC services to residential and commercial clients throughout the Austin area.

Advice for Employers

When hiring HVAC technicians, employers should prioritize candidates with certifications, strong technical skills, and a commitment to ongoing training. Investing in employee development and providing opportunities for advancement can help attract and retain top talent. Furthermore, a focus on safety and adherence to industry best practices is crucial for maintaining a safe and productive work environment. According to industry surveys, companies that prioritize employee training and development often experience lower turnover rates and higher levels of customer satisfaction.

Conclusion

Troubleshooting a silent outdoor AC unit requires a systematic approach, a solid understanding of HVAC principles, and the right tools. By following the steps outlined in this article, HVAC students, seasoned technicians, and employers can effectively diagnose and resolve common issues, ensuring optimal performance and longevity of AC systems. Remember to prioritize safety, adhere to industry best practices, and continue to invest in training and education to stay ahead in this dynamic and rewarding field.